Custom Sensors and OEM Solutions

FUTEK’s in-house multidisciplinary engineering team has led hundreds of custom sensor and OEM design programs—ranging from mission-critical NASA projects to miniature surgical robot applications. Our Engineer-to-Order (ETO) framework serves as the foundation of our new product development process. This structured approach—covering early design inputs, prototyping, validation under real-world conditions, and scaled manufacturing—guides development from concept through production. Depending on customer requirements, the ETO process can lead to either a standalone custom sensor or a fully integrated OEM sensing solution engineered for high-volume deployment in end-user systems.

Where are you in your project?

We offer tailored collaboration options to suit your project’s stage and complexity. Whether you need partial customization or full engineering-to-order solution, we’re here to support you.

Modify a Standard Sensor

Need a quick change? We can adapt catalog models with minor geometric or output modifications. Fast turnarounds, low NRE.

Co-Create a Custom Sensor

Have unique specs? Work with our team to design a sensor optimized for your size, environment, and performance needs.

Engineer-to-Order Solution

Looking for a full system integration? Our in-house team supports you from concept and electronics through V&V and manufacturing.

Request a Consultation / Quote

Benefits of Early Engagement

For R&D and new product development teams, engaging with a sensor manufacturer early in the process is critical to achieving the best results. Early collaboration allows custom sensors to be designed with the system’s mechanical and electrical requirements in mind, ensuring seamless integration and optimized performance. This has the added benefit of overall cost savings as potential issues can be assessed early in the process and dramatically reduce manufacturing and maintenance expenses. With our in-house design to manufacturing process, supported by fully developed quality processes and product/project management proficiency, FUTEK is able to accelerate the complex, resource-limited and multi-stakeholder new product development environment with improved time-to-market.

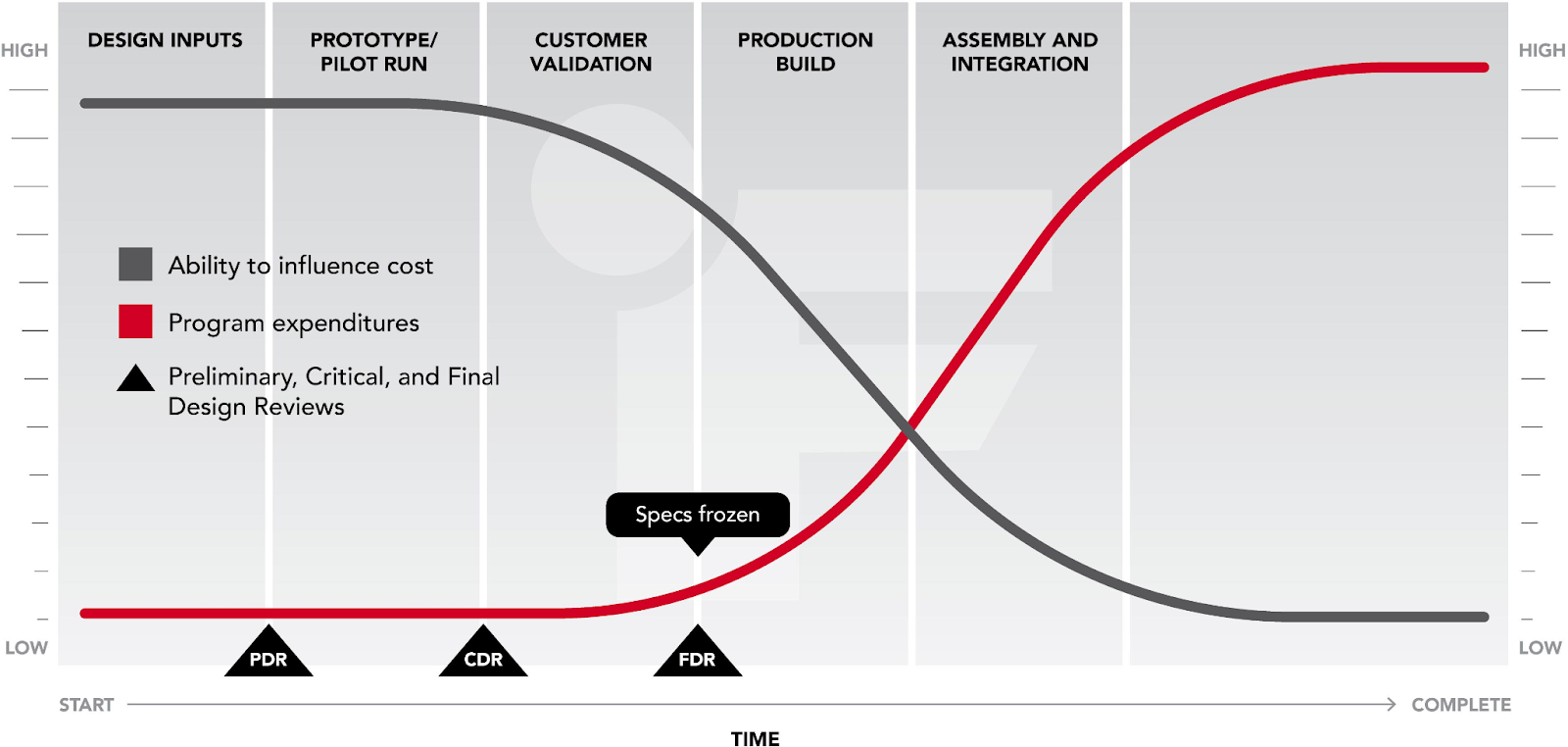

Why Early Engagement Matters

Design decisions made early—during the Design Inputs phase and before the PDR —have the greatest ability to influence cost. Engaging FUTEK early helps prevent expensive redesigns and avoid high-cost changes later in the process, when program expenditures start ramping up.

Early involvement allows risk factors to be identified and mitigated before reaching the CDR or FDR milestones. This reduces the likelihood of quality, compliance, or performance issues that may otherwise emerge when specs are frozen.

Collaborating early compresses the development timeline by aligning on design inputs, streamlining design review cycles, and minimizing design iteration loops after prototyping and system validation.

Sensors are designed to meet your system’s mechanical, electrical, and software constraints from day one, minimizing integration friction during the final assembly and verification phases.

Early input allows us to engineer for critical performance targets—such as linearity, repeatability, and signal conditioning —while still having the flexibility to adapt before specifications are locked at the Final Design Review (FDR).

Early alignment on materials, tolerances, and testing protocols ensures the final product can be efficiently built and scaled—avoiding costly adjustments once production begins and program expenditures peak.

Engineer-to-Order: A Proven Framework for Success

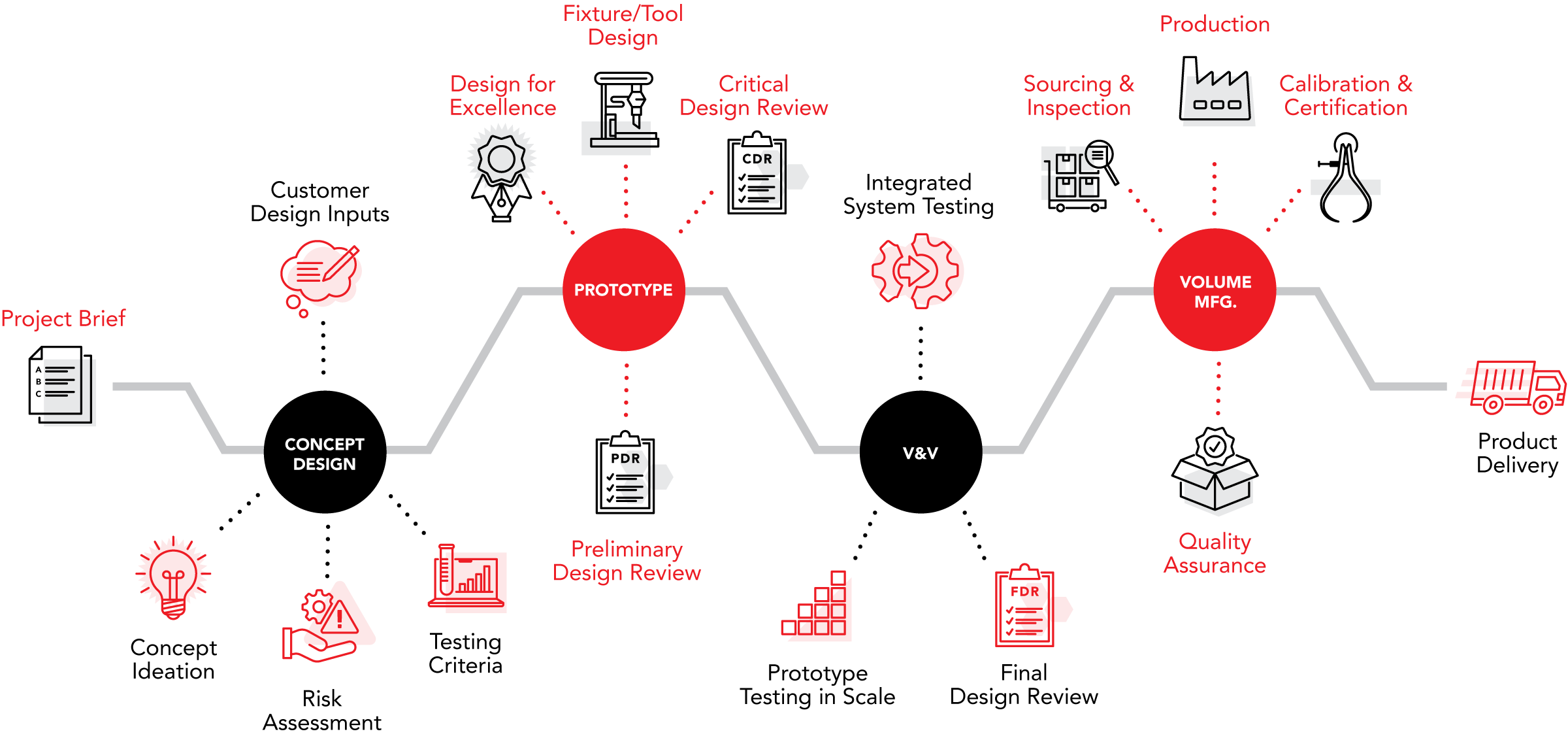

FUTEK’s Engineer-to-Order (ETO) framework is built to turn complex sensing challenges into fully integrated, high-performance solutions — from concept through scaled manufacturing. Whether you’re exploring a new application or refining an existing design, this structured process guides development through key phases: conceptual design, rapid prototyping, system validation, and volume production. Backed by in-house mechanical, electrical, and software engineering expertise, the ETO approach ensures risks are mitigated early, specifications are met, and long-term reliability is achieved—even in the most demanding environments. Depending on application scope and requirements, this framework can support anything from a single custom sensor to a fully integrated OEM sensing solution ready for high-volume deployment.

Concept Design

We translate your application requirements into actionable engineering inputs by combining mechanical, electrical, and software expertise to evaluate feasibility, assess risks, and define system specifications.

Prototype

Our in-house team rapidly builds and tests functional prototypes, combining mechanical design and custom electronics to validate performance early — accelerating design maturity and customer alignment.

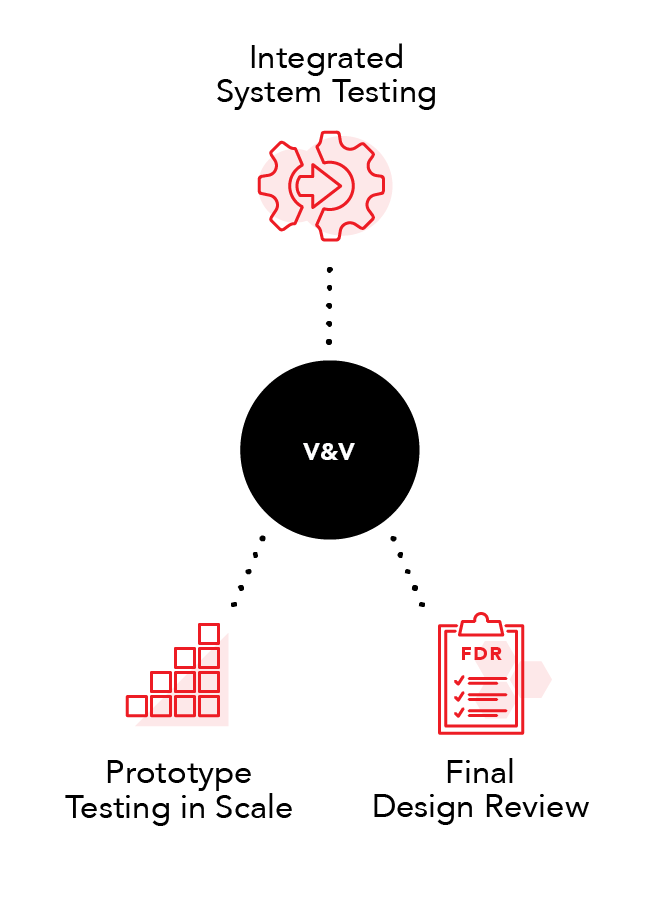

Verification & Validation (V&V)

Sensors are installed in the customer’s system for performance testing under real-world conditions. Our team supports this process, enabling refinements before full production to ensure specification compliance.

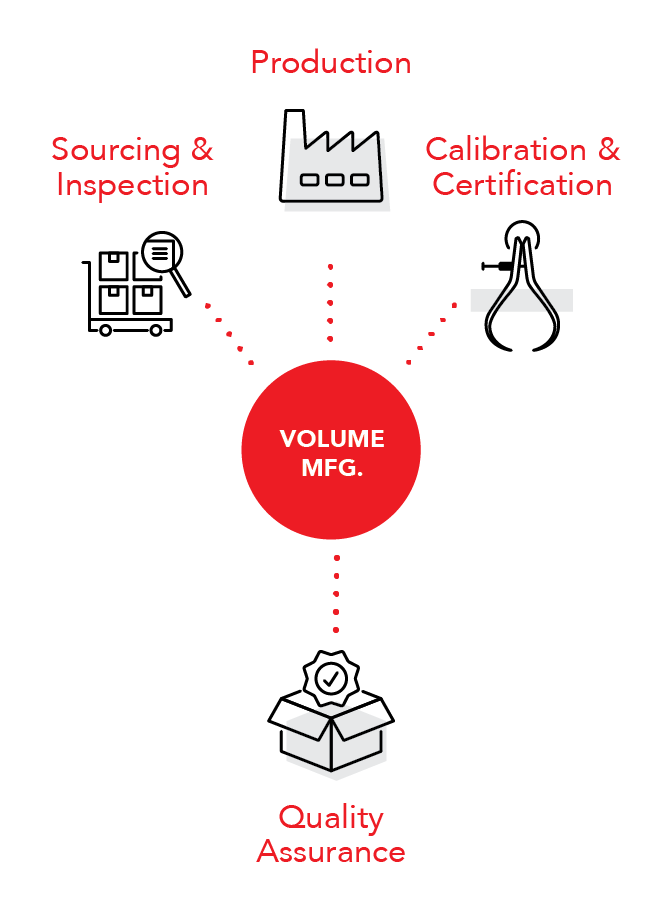

Volume Manufacturing

All manufacturing and calibration are done in-house to deliver fully validated sensor systems. Our ISO-certified processes ensure quality, repeatability, and on-time delivery for the most demanding applications.

Interested in the full engineering scope behind each stage? From feasibility studies to system integration and calibration, we’ve outlined the complete process below.

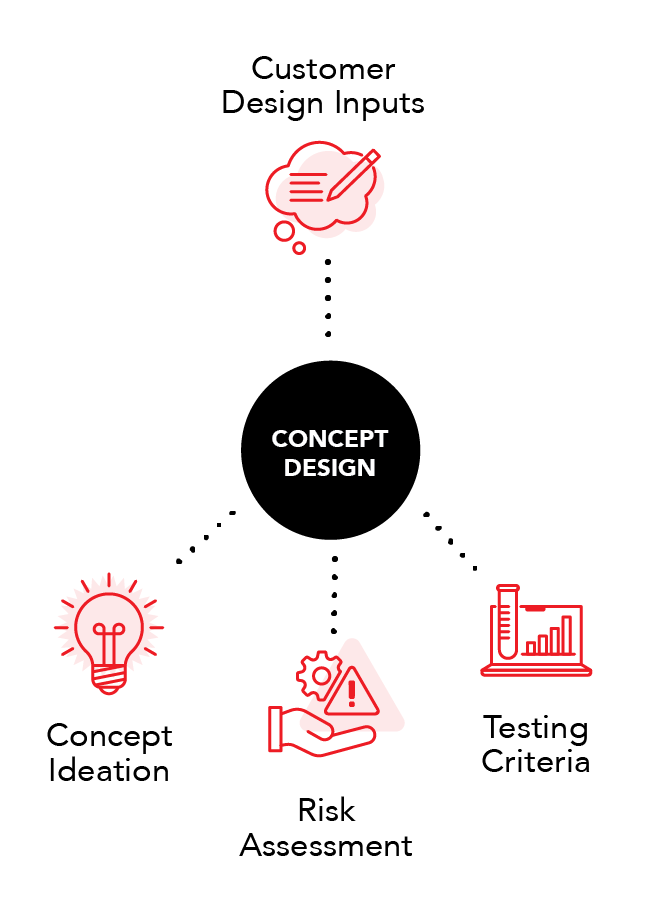

Concept Design

Every Engineer-to-Order (ETO) program begins with a deep understanding of the application and its constraints. At FUTEK, the Concept Design phase is a collaborative effort that transforms customer needs into actionable requirements through project briefs, design inputs, risk assessments, and testing criteria. This phase sets the foundation for the entire program. Our multidisciplinary engineering team—spanning mechanical, electrical, manufacturing and software design—integrates domain-specific expertise to evaluate technical feasibility and develop a high-fidelity conceptual framework. Leveraging engineering tools such as finite element analysis (FEA) and early DFM reviews, the team identifies potential roadblocks and designs around them, ensuring that performance targets, mechanical form factors, electronic signal integration, and cost parameters are addressed from the outset. This early-phase rigor is essential to minimizing risk and unlocking maximum design flexibility and cost efficiency.

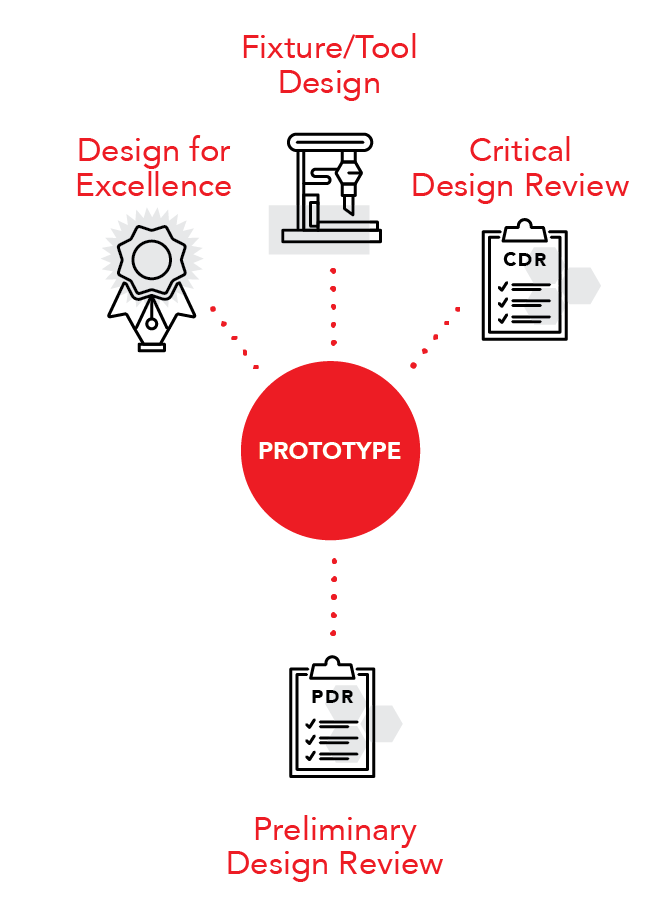

Prototype

The Prototype phase transforms early concepts into functional prototypes through rapid iteration and tight cross-functional collaboration. FUTEK’s in-house engineering team—including mechanical, electrical, and software engineers—works in lockstep to develop and refine both the sensor architecture and the supporting electronics. On the mechanical side, advanced tools such as 3D printing, precision machining, and fixture/tooling design support early-stage builds that evolve through Preliminary and Critical Design Reviews (PDR and CDR).

Simultaneously, FUTEK’s in-house electrical engineering team develops and integrates custom instrumentation solutions that meet demanding signal conditioning requirements. These electronic designs support both analog (mA, VDC) and digital outputs (UART, SPI, and USB), while achieving high sampling rates, broad bandwidth, high noise-free resolution, and low power consumption—all of which are essential for robust and reliable performance in modern embedded systems.

By combining these mechanical and electrical design efforts under one roof, FUTEK accelerates the prototyping timeline. This stage is pivotal in identifying integration challenges early, validating performance expectations, and preparing the design for scale-up—all while maintaining alignment with customer requirements and system-level constraints.

Verification & Validation (V&V)

During the Verification & Validation (V&V) phase, the focus shifts to system-level integration and performance testing—typically conducted by the customer within their own development or testing environment. At this stage, FUTEK’s sensor and signal conditioner are installed into the customer’s platform—such as a robotic arm, surgical tool, industrial machine, or aerospace structure—and evaluated as part of the full system. The objective is to observe how the complete measurement chain behaves under simulated real-world operating conditions.

Our goal is to enable customers to assess whether the sensing system—mechanical + electronic—meets the project’s performance criteria in context. These evaluations often include assessments of linearity, hysteresis, repeatability, signal stability, and interface compatibility. While many specifications are expected to be mature and stable at this point, FUTEK remains flexible and collaborative, recognizing that insights gained during full system integration may lead to refinements or a second design iteration in response to unexpected behaviors or new constraints discovered during V&V.

Mechanical robustness—such as tolerance to vibration, temperature cycling, or sterilization protocols—is also evaluated at this stage, especially for mission- or safety-critical applications. Our design philosophy emphasizes building sensor solutions that hold up not just in the lab, but in the final system—under load, in motion, and during customer-defined qualification cycles.

Volume Manufacturing

FUTEK’s Volume Manufacturing phase is grounded in process control, scalability, and manufacturing precision. All core operations—including machining, lamination, wiring, and sub-assembly—are performed in-house, giving us complete visibility and control over build quality, scheduling, and cost. Our Quality Assurance (QA) processes are embedded into each step of production, ensuring that components and assemblies meet the design intent and maintain tight tolerances required for high-performance sensing applications.

Sourcing and inspection are conducted under the same quality framework, and our teams apply Design for Manufacturability (DFM) principles from the start to reduce downstream costs and minimize variability. Once a product reaches final assembly—including the sensor, cable, and signal conditioner—it undergoes a comprehensive calibration and certification process, typically the final step before shipment. This system-level calibration verifies full signal chain performance and ensures the complete measurement system is traceable and compliant with customer specifications.

FUTEK’s commitment to quality is backed by ISO 13485 certification for medical-grade manufacturing processes and ISO 17025-accredited calibration laboratories. This ensures that every unit we ship—whether a one-off custom solution or a high-volume production run—is validated, traceable, and ready for mission-critical deployment. This fully integrated and quality-driven manufacturing model is how FUTEK consistently delivers repeatable, high-performance sensing systems at scale—with confidence.

Request a Consultation / Quote

Bridging Conceptual Design and Volume Manufacturing with Proven Project Management

Delivering complex Engineer-to-Order (ETO) solutions requires more than technical excellence—it demands disciplined program execution. At FUTEK, our project and product managers bring certified expertise in both waterfall and agile methodologies to ensure on-time, on-budget delivery of custom sensor programs. We proactively coordinate cross-functional teams, manage change request, and align stakeholders throughout the development lifecycle—from initial scope definition to final delivery. With a strong emphasis on risk mitigation, schedule control, and cost transparency, we integrate engineering milestones, design reviews, supply chain, procurement cycles, and manufacturing timelines into a cohesive and responsive execution plan.

Explore our Custom Sensor Portfolio

FUTEK’s custom engineering expertise spans load cells, torque sensors, multi-axis sensors, and signal conditioning electronics—each designed to solve unique performance challenges in highly demanding applications. Explore our catalog of field-proven designs as a starting point for your next Engineer-to-Order solution. Whether you're looking to slightly modify an off-the-shelf (MOTS) model or develop a custom sensor from the ground up, these pages provide a gateway into what’s possible.

Why trust FUTEK for your custom sensor development?

FUTEK’s proven track record in precision engineering, mission-critical environments, and cross-industry innovation enables us to develop sensing solutions that meet the highest levels of technical, environmental, and regulatory complexity. Whether it’s designing ultra-miniature sensors for surgical robots, radiation-tolerant systems for aerospace, or IP-rated solutions for industrial automation, our vertically integrated facility and multidisciplinary team deliver both flexibility and repeatability. From cryogenics to autoclave sterilization, from non-magnetic materials to multi-bridge outputs, our engineering and manufacturing capabilities are designed to meet the unique mechanical, electrical, and environmental demands of your application—with confidence.

Discover how our sensors are optimized to suit your requirements.

Space-Constrained Design

FUTEK is an industry leader in sensor miniaturization and space-constrained design, developing lightweight, compact models that fit tight mechanical envelopes while delivering the same precision and performance as standard-sized sensors.

Retrofit Design

FUTEK provides custom sensors designed to integrate seamlessly into existing assemblies, ensuring minimal disruption to your architecture without reengineering the entire system.

Up to IP69K

We offer sensors designed to meet IP67, IP68, and IP69K ingress protection standards, enabling operation in harsh environments with high-pressure washdowns, moisture, or dust exposure.

High Temperature Compensated

Our sensors are engineered with temperature compensation techniques to ensure accurate performance across extreme thermal environments—without drift or signal degradation under fluctuating or elevated temperatures.

Cryogenics

Our sensors perform perfectly in extreme temperatures. For example, for the Raytheon VIIRS Satellite project we produced two cryogenic sensors able to withstand –300°F (–184°C).

Fatigue rated

We make sensors with extreme durability that endure fatigue tests through millions of cycles. There’s a reason why our sensors on Mars have operated impeccably since 2012.

Vacuum-Compatible

We work closely with the end user to understand what out-gassing requirements they may have so we can tailor our designs to meet their needs.

Non-Magnetic

FUTEK offers sensor solutions constructed with non-magnetic materials, ideal for use in magnetic-sensitive environments, or applications where electromagnetic interference must be minimized.

Overload Protection

FUTEK’s proprietary EDM machining technology has allowed us to pioneer space-graded sensors with 60x integrated and bidirectional overload protection. Traditional sensors typically have 150% safe overload.

Shock and vibration resistant

FUTEK introduced the industry-first spike shock resistant force sensor in 2001. Since then, we have worked with best-in-class laboratories to continue to perfect our sensors’ performance.

Autoclave/Sterilizable

FUTEK designs sensors capable of withstanding repeated autoclave cycles and sterilization processes, making them ideal for medical applications that demand high hygiene or decontamination standards.

Radiation tolerance

We have the capabilities to engineer and develop space-grade sensors with radiation tolerance. We are confident that we can meet your requirements and even surpass your expectations.