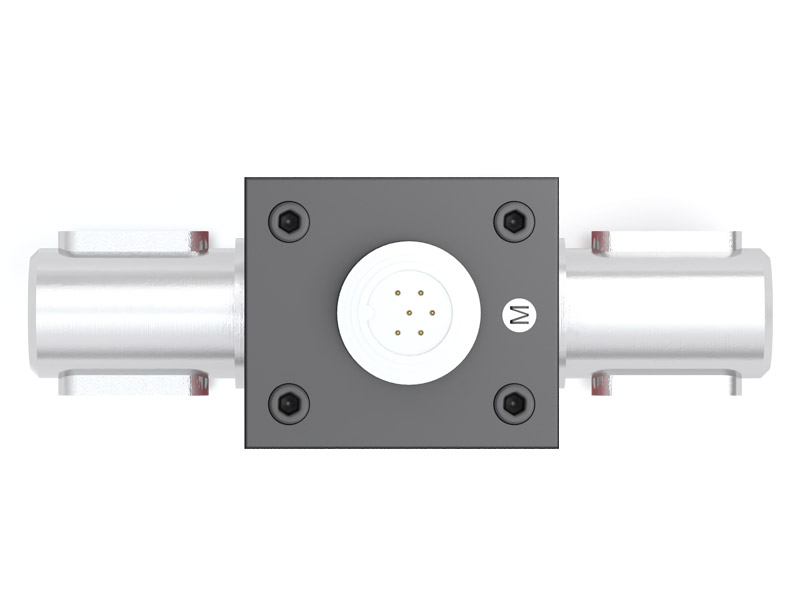

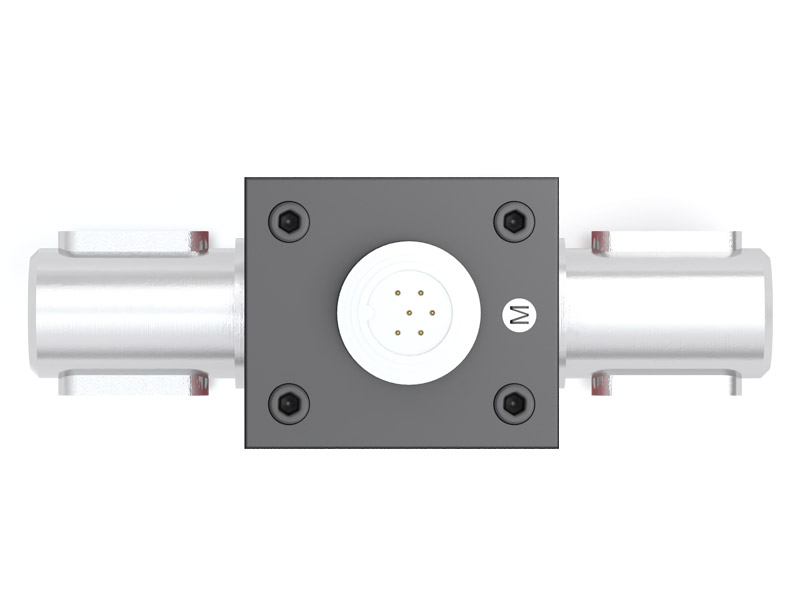

Slip-Ring Shaft-to-Shaft Rotary Torque Sensor

High stiffness and accuracy with easy installation

Description

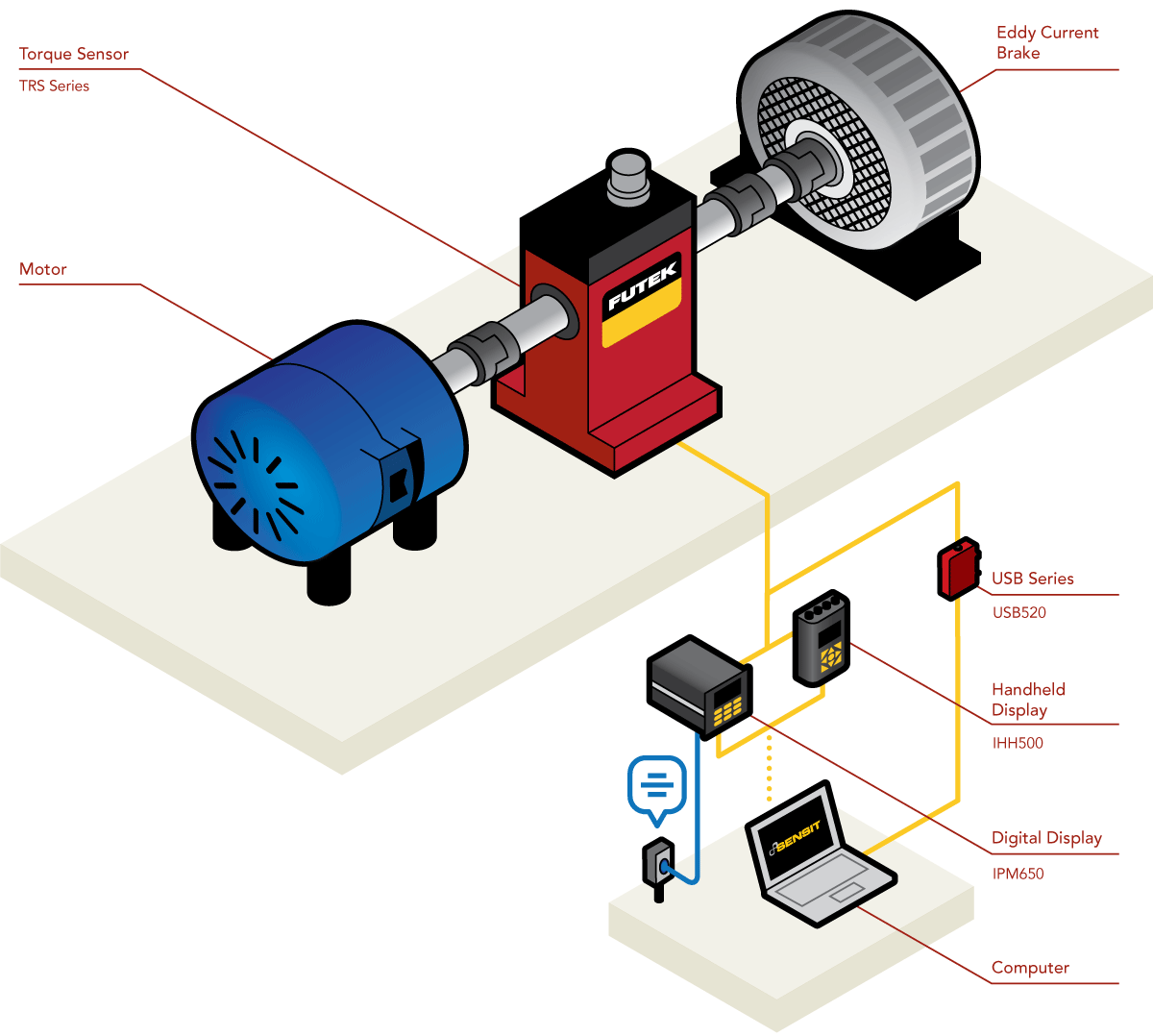

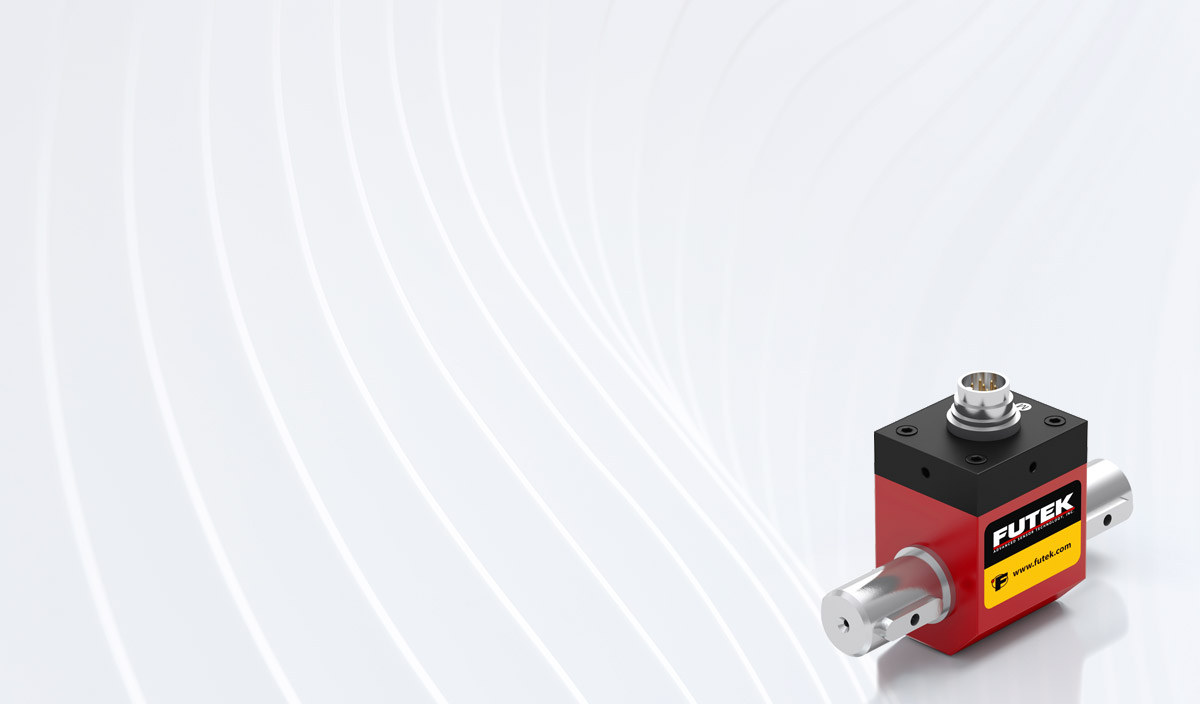

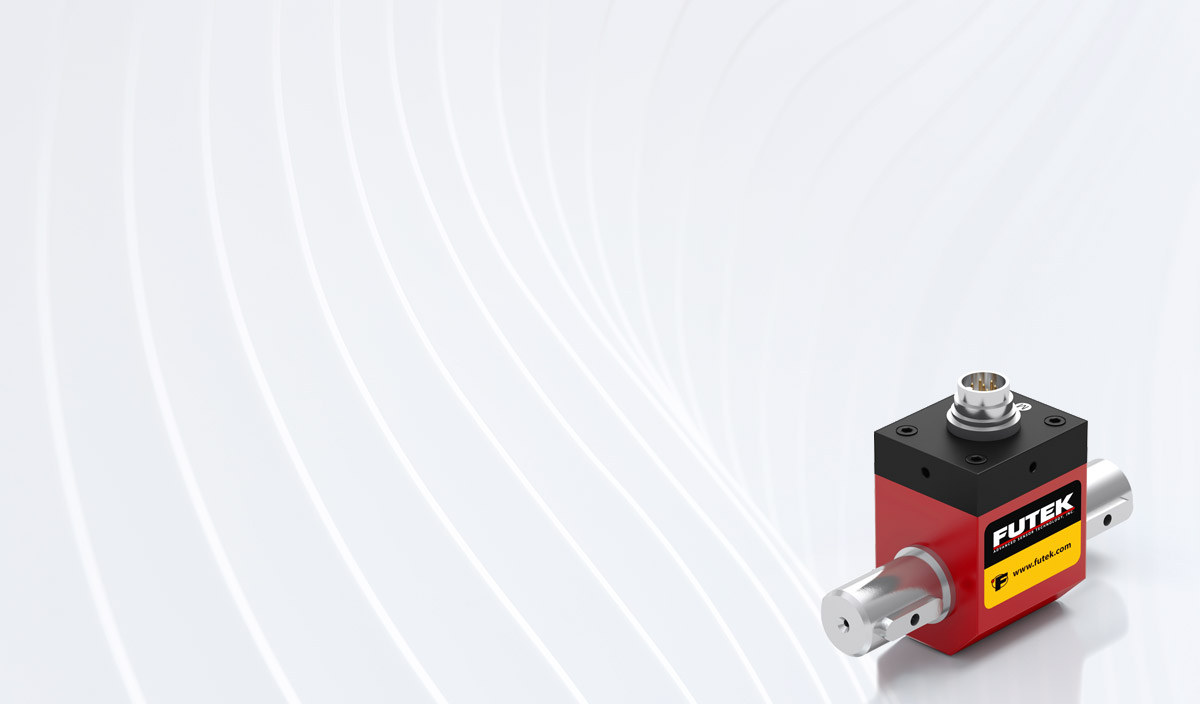

FUTEK’s Rotary Torque Sensor - Shaft to Shaft offers a unique solution for torque auditing applications. The TRS300 Shaft to Shaft Rotary Torque Sensor is available in a wide capacity range and utilizes strain gauge technology.

Product Highlights And Features

- Configures with external mating electronics

- Slip ring-based torque sensor

- Compact size

- Designed for lower duty cycles

- Can operate up to 3000 RPM

TRS300 is a compact shaft-to-shaft rotary torque sensor (or rotary torque transducer) with seven capacities covering a wide torque range of 10 Nm to 1000 Nm. The model has two sizes, a smaller one for the four lower capacities and a larger size for the three higher capacities. It’s a highly accurate rotary torque sensor with nonlinearity better than ±0.2% of rated output. TRS300 features a low noise/high resolution slip ring and brush pair design that allows for a precise transfer of the signal from the rotating shaft. The design is ideally suited for measuring clockwise and counterclockwise rotational torque under lower speeds (supports up to 3000 RPM) and lower cycles.

High stiffness

The rotary torque sensor’s design and alloy steel shaft provides high stiffness, resulting in TRS300’s high frequency response rate and ability to maintain accuracy.

Made to be accurate

The TRS300’s slip ring allows for the electrical signal to transfer from a rotating component to the stator, allowing direct measurement of dynamic torque changes. High precision machining of the components allows for accurate reading and reliability.

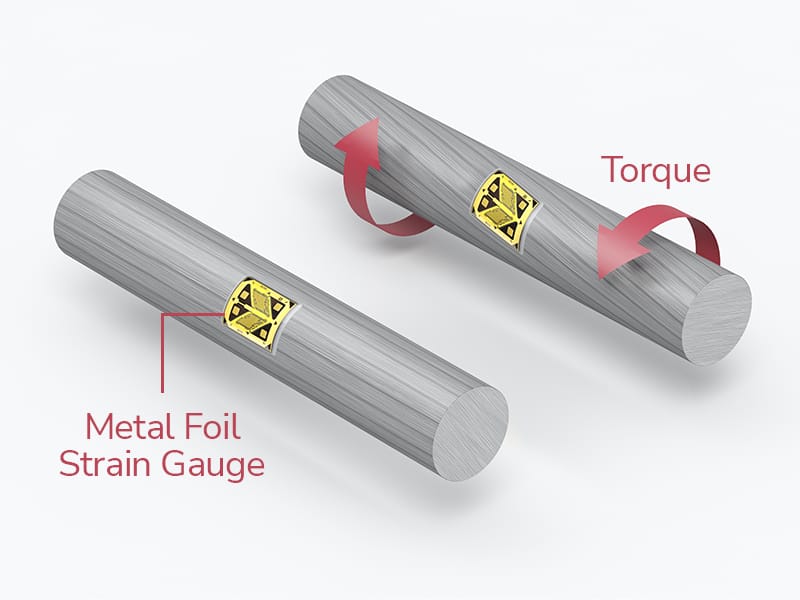

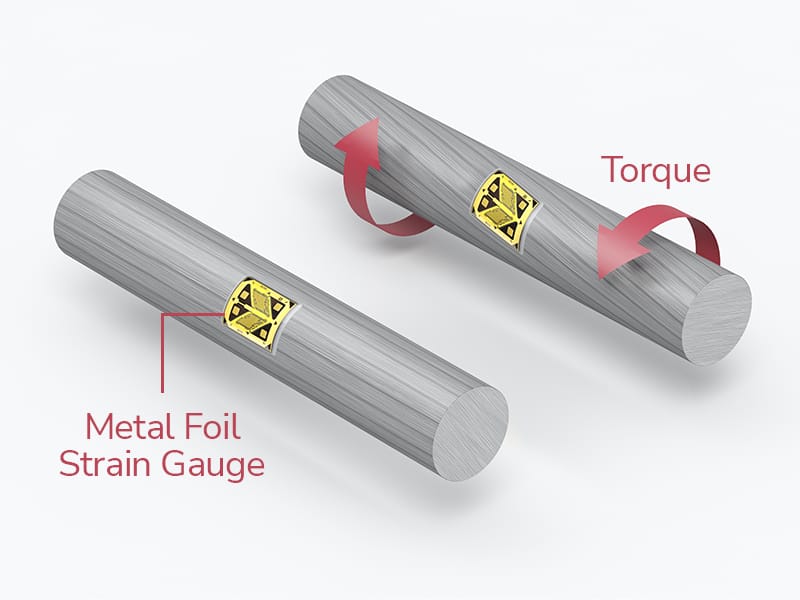

Reliable strain gauge technology

TRS300 uses bonded foil strain gauge technology, which offers higher reliability, longer product life, and more immunity to vibrational damages than competing technologies. It also performs well under a wider operational temperature range.

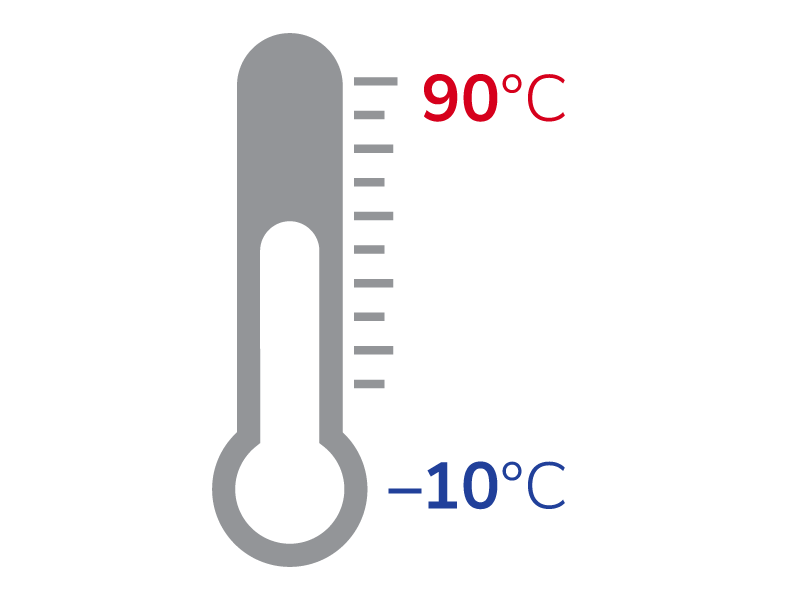

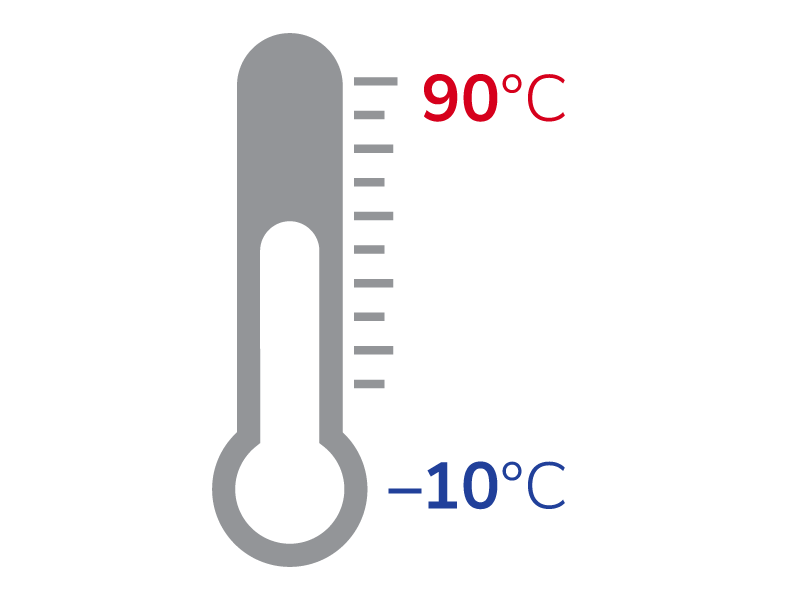

Temperature Compensation Capabilities

The TRS300 has a reliable performance over a wide temperature range of 14 to 194°F (–10 to 90°C) and provides compensated data in the 41 to 122°F (5 to 50°C) range, allowing you to use the sensor in various applications and environments.

Connectivity

The TRS300’s output can be easily converted to high level voltage (VDC), current (mA), digital USB or others and to be connected to display devices or other controllers directly. FUTEK provides various cables as well as display devices (IHH500 or the USB output kit series). which can be configured with the rotary torque sensors. Since the output of TRS300 is in low level mV/V, FUTEK’s IAA amplifiers can be used if required.

Wide range of applications

The TRS rotary torque series is suited for inline measurement or motor torque applications like electric motor efficiency measurement, in line motor torque measurement, industrial robotic automation, monitoring of regenerative braking efficiency (in electric vehicles), fatigue testing of hinges and numerous other laboratory and industrial applications.

Easy installation

The inline shaft-to-shaft design allows for simple and easy installation. A robust 6-pin binder provides the connectivity for two input excitations and two signal output leads. The detachable feather keyway is 6mm wide for the smaller models (19mm shaft dia.) and 10mm wide for the larger models (38mm shaft dia.) Please ensure the use of couplings to achieve proper inline positioning.

Calibration available

A certificate of conformance can be ordered on request. The sensor will be rigorously tested by FUTEK’s world class calibration department whose proprietary and innovative processes exceed the stringent ANSI Z540-1 and ISO 17025 standards. We can also reduce your setup time by calibrating your sensor of choice with an amplifier.

High stiffness and accuracy with easy installation

Description

FUTEK’s Rotary Torque Sensor - Shaft to Shaft offers a unique solution for torque auditing applications. The TRS300 Shaft to Shaft Rotary Torque Sensor is available in a wide capacity range and utilizes strain gauge technology.

Product Highlights And Features

- Configures with external mating electronics

- Slip ring-based torque sensor

- Compact size

- Designed for lower duty cycles

- Can operate up to 3000 RPM

TRS300 is a compact shaft-to-shaft rotary torque sensor (or rotary torque transducer) with seven capacities covering a wide torque range of 10 Nm to 1000 Nm. The model has two sizes, a smaller one for the four lower capacities and a larger size for the three higher capacities. It’s a highly accurate rotary torque sensor with nonlinearity better than ±0.2% of rated output. TRS300 features a low noise/high resolution slip ring and brush pair design that allows for a precise transfer of the signal from the rotating shaft. The design is ideally suited for measuring clockwise and counterclockwise rotational torque under lower speeds (supports up to 3000 RPM) and lower cycles.

High stiffness

The rotary torque sensor’s design and alloy steel shaft provides high stiffness, resulting in TRS300’s high frequency response rate and ability to maintain accuracy.

Made to be accurate

The TRS300’s slip ring allows for the electrical signal to transfer from a rotating component to the stator, allowing direct measurement of dynamic torque changes. High precision machining of the components allows for accurate reading and reliability.

Reliable strain gauge technology

TRS300 uses bonded foil strain gauge technology, which offers higher reliability, longer product life, and more immunity to vibrational damages than competing technologies. It also performs well under a wider operational temperature range.

Temperature Compensation Capabilities

The TRS300 has a reliable performance over a wide temperature range of 14 to 194°F (–10 to 90°C) and provides compensated data in the 41 to 122°F (5 to 50°C) range, allowing you to use the sensor in various applications and environments.

Connectivity

The TRS300’s output can be easily converted to high level voltage (VDC), current (mA), digital USB or others and to be connected to display devices or other controllers directly. FUTEK provides various cables as well as display devices (IHH500 or the USB output kit series). which can be configured with the rotary torque sensors. Since the output of TRS300 is in low level mV/V, FUTEK’s IAA amplifiers can be used if required.

Wide range of applications

The TRS rotary torque series is suited for inline measurement or motor torque applications like electric motor efficiency measurement, in line motor torque measurement, industrial robotic automation, monitoring of regenerative braking efficiency (in electric vehicles), fatigue testing of hinges and numerous other laboratory and industrial applications.

Easy installation

The inline shaft-to-shaft design allows for simple and easy installation. A robust 6-pin binder provides the connectivity for two input excitations and two signal output leads. The detachable feather keyway is 6mm wide for the smaller models (19mm shaft dia.) and 10mm wide for the larger models (38mm shaft dia.) Please ensure the use of couplings to achieve proper inline positioning.

Calibration available

A certificate of conformance can be ordered on request. The sensor will be rigorously tested by FUTEK’s world class calibration department whose proprietary and innovative processes exceed the stringent ANSI Z540-1 and ISO 17025 standards. We can also reduce your setup time by calibrating your sensor of choice with an amplifier.