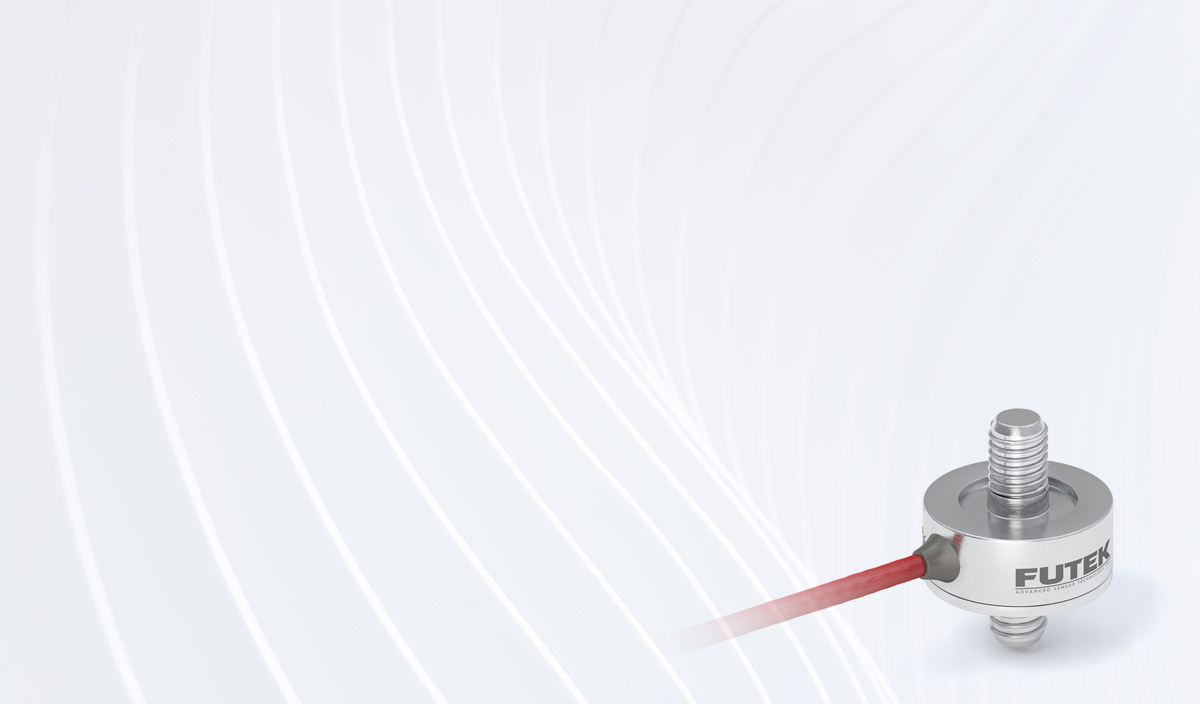

Micro Miniature Threaded In Line Load Cell

Ultra-small footprint for inline applications

Description

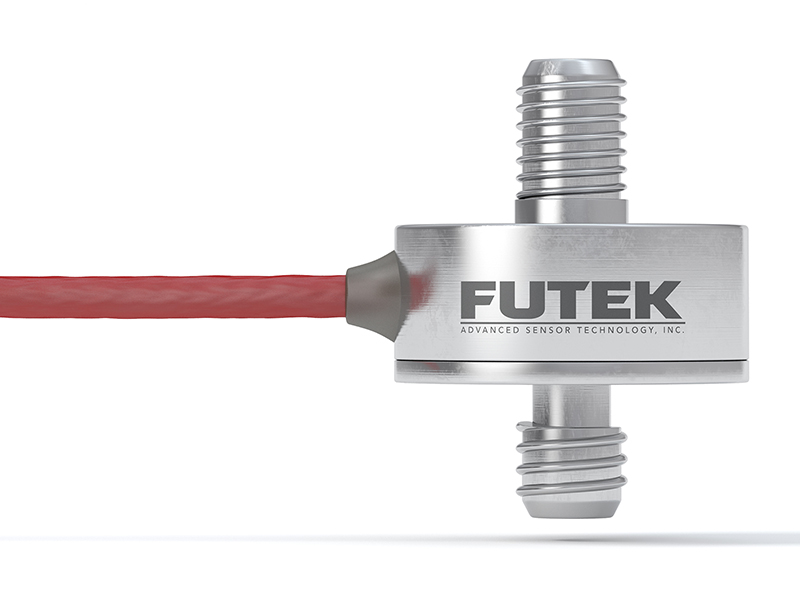

Model LCM100 is a Miniature Threaded In Line Load Cell built for Endurance or Inline Tension or Compression applications. The standard LCM100 Miniature Threaded In Line Load Cell Model has a very robust construction available in 17-4 Stainless Steel, with male threads on both ends and a 5 foot #34 Awg 4 conductor braided shielded cable. This product offers an exceptional weight of 0.3 oz (8.5 g). The LCM100 model is also CE and RoHS compliant.

The LCM100 miniature load cell offers high accuracy. It has nonlinearity of ±0.5% of RO and deflection of 0.0001 in to 0.0002 in nominal. The standard LCM100 Miniature Tension and Compression Load Cell can be modified or customized to meet your requirements and most capacities are in our inventory, making them available for 24 hour shipping. Similar to our entire Load Cell product line this model is manufactured in the USA and uses metal foil strain gauge technology.

Product Highlights And Features

- High speed, low deflection micro load cell

- Minimal mounting clearance

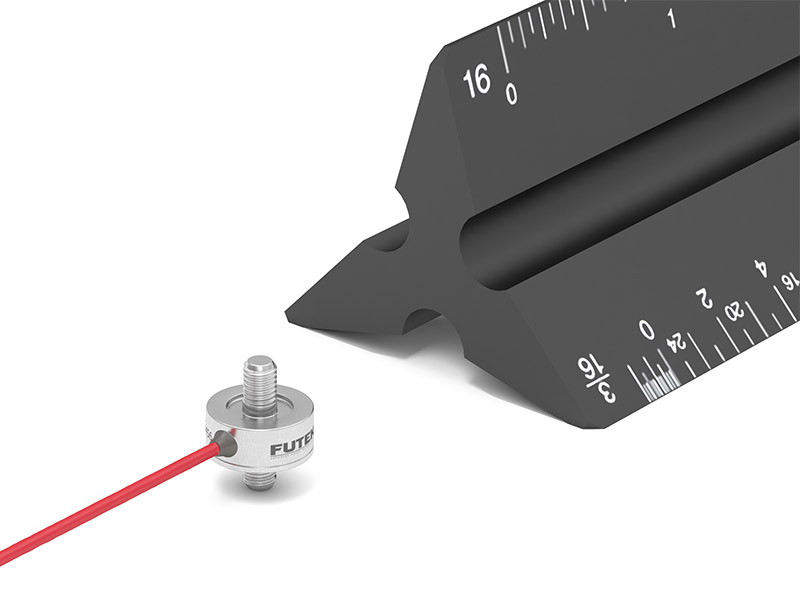

- Outer diameter of 0.38” [9.5 mm]

- 17-4 PH stainless-steel construction

- For use in both tension and compression

- Utilizes metal foil strain gauge technology

- Adheres to RoHS directive 2015/863/EU

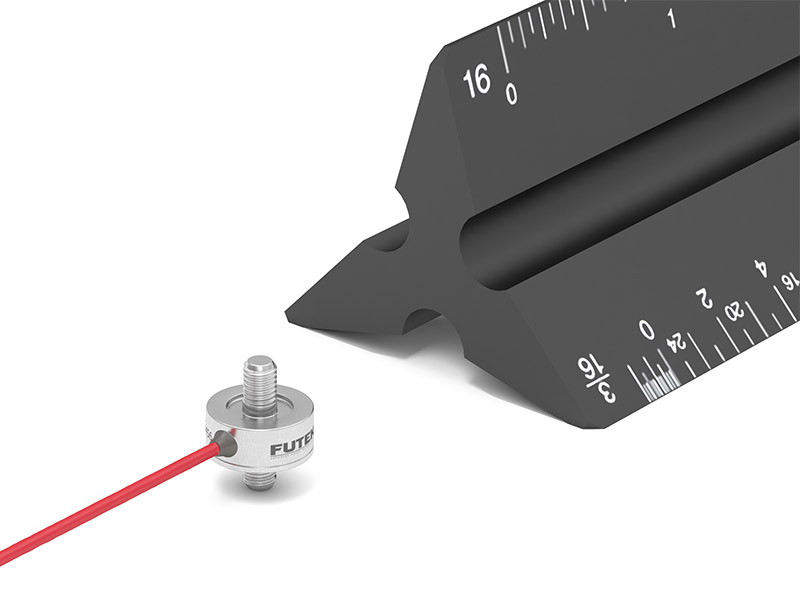

The micro rod end sensor LCM100 is the smallest inline male threaded solution in FUTEK’s catalog. Measuring just 0.38in (9.5mm) in diameter and 0.17in (4.2mm) in minimal clearance height, this micro diaphragm solution utilizes versatile M3 male thread mounting provisions. It provides an ultra fast response in both tension and compression loading with a capacity range of 2.2 to 50lb (1 to 22.6kg).

The LCM100 is particularly well suited for inline applications with size constraints, such as surgical robotics, as it adds minimal increase in outer diameter or height to the assembly. The LCM100 is offered with a jacketed cable that is designed for repeated flex cycles. This model can also be modified to suit OEM applications. FUTEK offers application and engineering resources during DFM/DFX stage upon request.

Minimal mounting clearance

The minimal mounting clearance of the LCM100 makes it ideal for applications that require a tiny footprint without sacrificing accuracy and durability. It’s particularly beneficial for linear actuators in surgical robotics or very small processing or automation equipment where tension or compression forces are measured inline.

Made to be accurate

The LCM100 has a maximum non-linearity of ±0.5%. The precision of the sensor is also augmented by its high stiffness, which leads to a very low deflection. In addition, special design and manufacturing touches further enhance the sensor’s performance, such as a custom strain gage that further reduces influences of eccentric load.

Dust and water jet resistant

LCM100 models with a jacketed cable have an an IP65 rating, which means they can withstand dust and direct water spray. This opens up more options for applications in most dusty environments and those where there are washdown environments.

Easy mounting

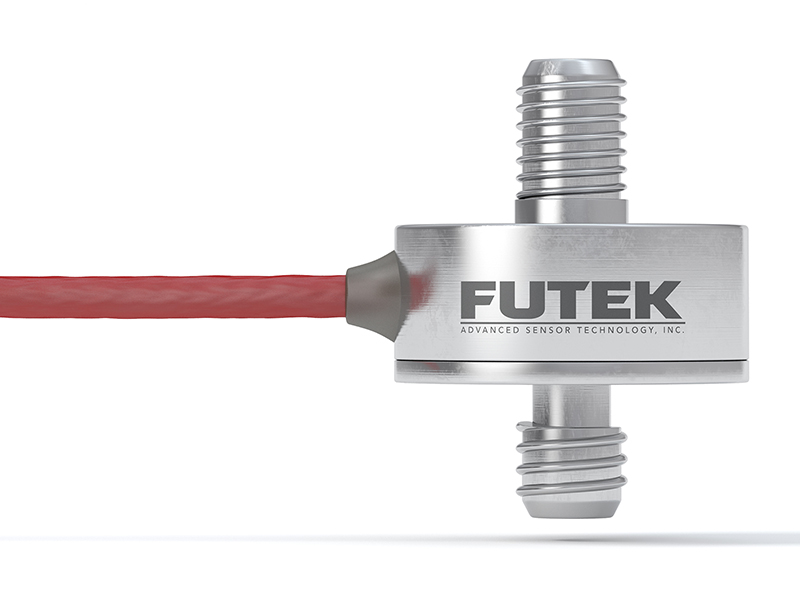

The LCM100 has male threads on both ends for easy and flexible mounting options. Also, the compact design allows you to mount it in different locations, especially for applications with very limited space.

Interior thermal compensation

The LCM100 features a monolithic sensing element with integrated zero balance and thermal compensation, which reduces the risk of accidentally removing compensation circuitry. It also offers flexibility for cable routing and customization of the cable length. The sensor’s robust construction enhances and ensures unmatched sensor performance, reliability and environmental protection.

Allows flexible loading options

The flexible male threaded loading provision allows users to create their own end effectors, if, for example, there's a need for a non-conductive or less abrasive setup. Hence, the user can easily achieve the optimal loading provision for their application.

Welded construction

The seam-welded body provides enhanced protection against physical damage in addition to withstanding other harsh environmental conditions. A special heat treatment process has been applied to the flexure to improve durability, extending the life-cycle of the sensor.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, low hysteresis and creep properties, and corrosion resistance over a wide temperature range.

Cable designed for flex

The LCM100 is also available with a polyester jacketed cable that is floating on the sensor body and is designed for flex. It’s ideal for applications that require travel or constant handling. The jacket covers the signal wires while significantly reducing interference from electrical noise.

Calibration included

The LCM100 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

Ultra-small footprint for inline applications

Description

Model LCM100 is a Miniature Threaded In Line Load Cell built for Endurance or Inline Tension or Compression applications. The standard LCM100 Miniature Threaded In Line Load Cell Model has a very robust construction available in 17-4 Stainless Steel, with male threads on both ends and a 5 foot #34 Awg 4 conductor braided shielded cable. This product offers an exceptional weight of 0.3 oz (8.5 g). The LCM100 model is also CE and RoHS compliant.

The LCM100 miniature load cell offers high accuracy. It has nonlinearity of ±0.5% of RO and deflection of 0.0001 in to 0.0002 in nominal. The standard LCM100 Miniature Tension and Compression Load Cell can be modified or customized to meet your requirements and most capacities are in our inventory, making them available for 24 hour shipping. Similar to our entire Load Cell product line this model is manufactured in the USA and uses metal foil strain gauge technology.

Product Highlights And Features

- High speed, low deflection micro load cell

- Minimal mounting clearance

- Outer diameter of 0.38” [9.5 mm]

- 17-4 PH stainless-steel construction

- For use in both tension and compression

- Utilizes metal foil strain gauge technology

- Adheres to RoHS directive 2015/863/EU

The micro rod end sensor LCM100 is the smallest inline male threaded solution in FUTEK’s catalog. Measuring just 0.38in (9.5mm) in diameter and 0.17in (4.2mm) in minimal clearance height, this micro diaphragm solution utilizes versatile M3 male thread mounting provisions. It provides an ultra fast response in both tension and compression loading with a capacity range of 2.2 to 50lb (1 to 22.6kg).

The LCM100 is particularly well suited for inline applications with size constraints, such as surgical robotics, as it adds minimal increase in outer diameter or height to the assembly. The LCM100 is offered with a jacketed cable that is designed for repeated flex cycles. This model can also be modified to suit OEM applications. FUTEK offers application and engineering resources during DFM/DFX stage upon request.

Minimal mounting clearance

The minimal mounting clearance of the LCM100 makes it ideal for applications that require a tiny footprint without sacrificing accuracy and durability. It’s particularly beneficial for linear actuators in surgical robotics or very small processing or automation equipment where tension or compression forces are measured inline.

Made to be accurate

The LCM100 has a maximum non-linearity of ±0.5%. The precision of the sensor is also augmented by its high stiffness, which leads to a very low deflection. In addition, special design and manufacturing touches further enhance the sensor’s performance, such as a custom strain gage that further reduces influences of eccentric load.

Dust and water jet resistant

LCM100 models with a jacketed cable have an an IP65 rating, which means they can withstand dust and direct water spray. This opens up more options for applications in most dusty environments and those where there are washdown environments.

Easy mounting

The LCM100 has male threads on both ends for easy and flexible mounting options. Also, the compact design allows you to mount it in different locations, especially for applications with very limited space.

Interior thermal compensation

The LCM100 features a monolithic sensing element with integrated zero balance and thermal compensation, which reduces the risk of accidentally removing compensation circuitry. It also offers flexibility for cable routing and customization of the cable length. The sensor’s robust construction enhances and ensures unmatched sensor performance, reliability and environmental protection.

Allows flexible loading options

The flexible male threaded loading provision allows users to create their own end effectors, if, for example, there's a need for a non-conductive or less abrasive setup. Hence, the user can easily achieve the optimal loading provision for their application.

Welded construction

The seam-welded body provides enhanced protection against physical damage in addition to withstanding other harsh environmental conditions. A special heat treatment process has been applied to the flexure to improve durability, extending the life-cycle of the sensor.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, low hysteresis and creep properties, and corrosion resistance over a wide temperature range.

Cable designed for flex

The LCM100 is also available with a polyester jacketed cable that is floating on the sensor body and is designed for flex. It’s ideal for applications that require travel or constant handling. The jacket covers the signal wires while significantly reducing interference from electrical noise.

Calibration included

The LCM100 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.