Non-Contact Shaft-to-Shaft Rotary Torque Sensor

High stiffness and accuracy with non-contact shaft

Description

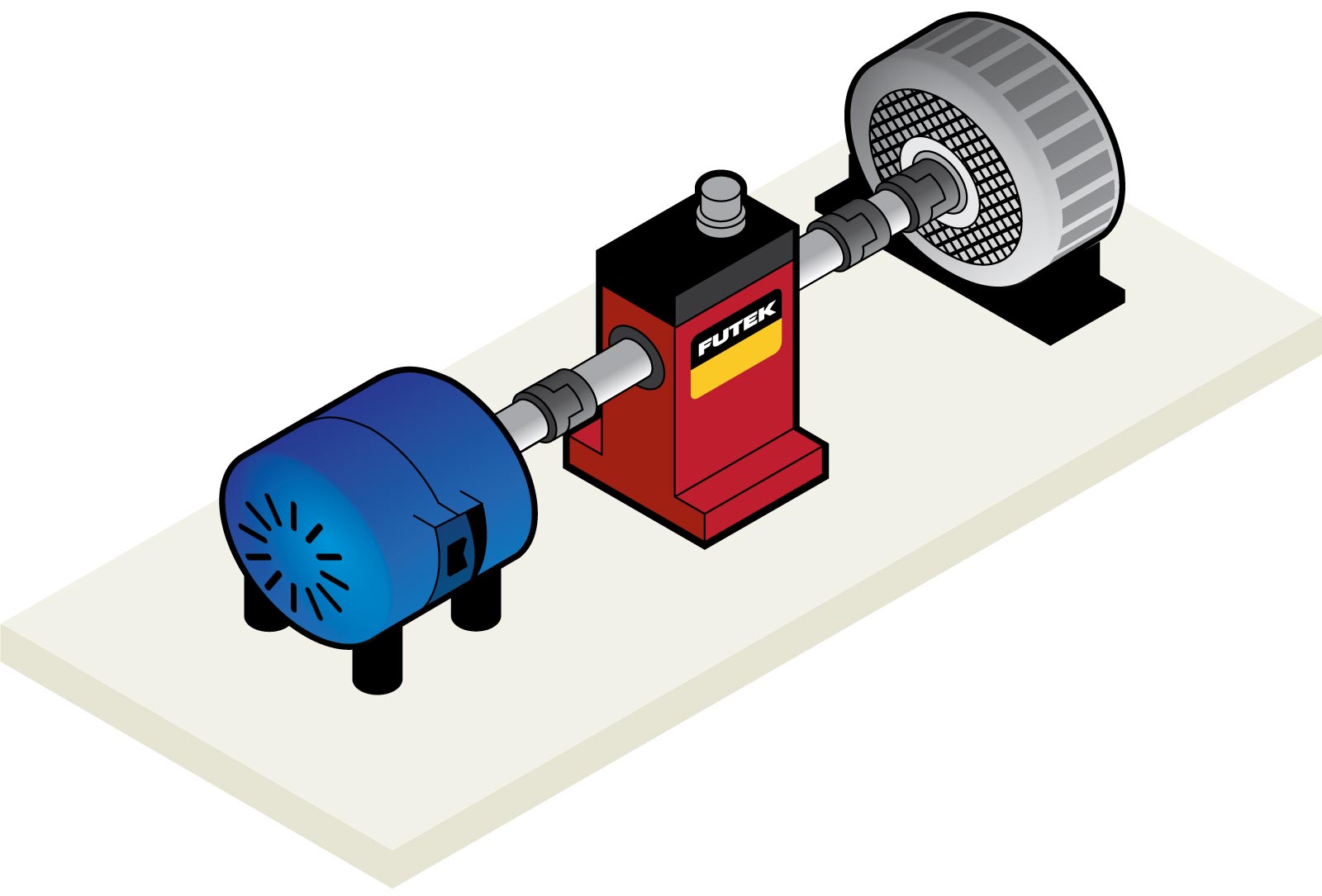

FUTEK’s Rotary Torque Sensor - Non contact shaft to shaft offers a unique solution for torque auditing applications. The TRS600 Rotary Torque Sensor - Non contact shaft to shaft is available in a wide capacity range and utilizes strain gauge technology. FUTEK's TRS Series is also available with a TEDS / IEEE1451.4 option.

Product Highlights And Features

- Utilizes strain gauge technology

- Compact size

- Can operate up to 12000 RPM (9-89 in-lb)

The TRS600 is a compact shaft-to-shaft rotary torque sensor that provides highly accurate and repeatable measurements in both clockwise and counter clockwise directions. The reactionary shaft allows torque measurements with and without rotation, making it suitable for low and high speed, as well as no speed applications. Some capacities operate at speeds up to 12,000 RPM. Its 7 capacities (which come in different sizes) cover a wide torque range of 1 Nm to 100 Nm. Despite its broad capacity range and high RPM, its compact size range allows for applications with tight spaces. This non-contact rotary torque sensor is an excellent choice for dynamic applications with higher lifespan as it is durable and low maintenance. The design allows for overload protection for up to 150% of the rated output.

Made to be accurate

Due to its high stiffness and low inertia, TRS600 has a nonlinearity of ±0.2% of rated output and is able to maintain accuracy. The high stiffness of the design allows for measurements of dynamic torque changes, including monitoring of intermittent shaft rotations.

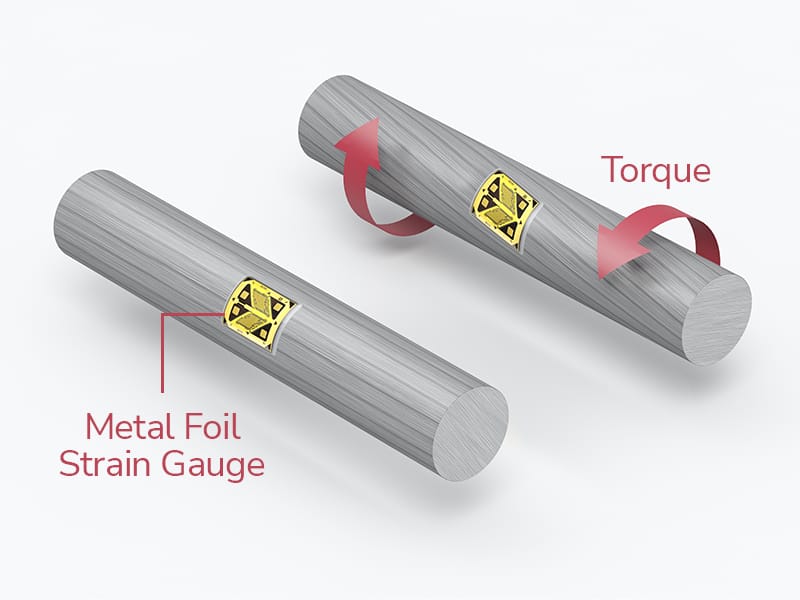

Reliable strain gauge technology

TRS600 uses bonded foil strain gauge technology, which offers higher reliability, longer product life, and more immunity to vibrational damages than competing technologies. It also performs well under a wider operational temperature range.

Non-Contact Signal Transfer

Differently from traditional slip rings torque sensors with brushes that make contact with slip rings, TRS600 is equipped with non-contact signal transfer, which increases durability with minimal maintenance.

Low power consumption

The TRS600 has a low power consumption of just 1 W. This is especially valuable for any applications that are battery operated or are embedded in tight spaces where heat generation could become an issue.

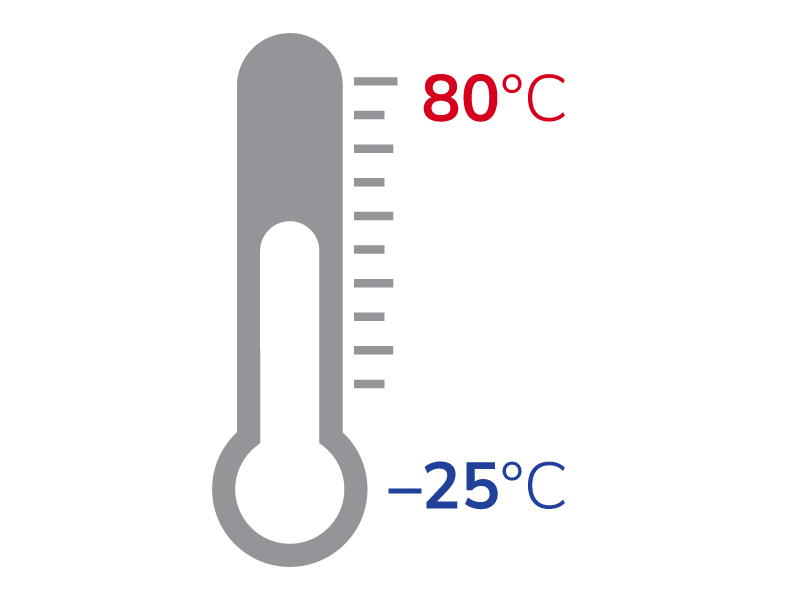

Temperature Compensation Capabilities

The TRS600 provides reliable performance over a wide temperature range of –13 to 176°F (–25 to 80°C) and compensates for temperature variation data in the 41 to 122°F (5 to 50°C) range, allowing you to use the sensor in various applications and environments.

Easy installation

Inline shaft-to-shaft design allows for simple and easy installation. The robust 12-pin binder provides the connectivity for signal input and output. The higher capacities feature detachable keys. Please ensure the use of couplings to achieve proper inline positioning.

Flexible connectivity

The TRS600’s outputs can be connected to display devices or other controllers directly. FUTEK provides various cables as well as display devices such as the digital handheld IHH500 or the USB output kit series which can be configured with the sensors. TRS600 is equipped with an embedded signal conditioner, and its output is in amplified ± VDC analog output. Since its output is in VDC amplified range, no additional signal amplification or conditioning is required to support interconnection with Data Acquisition Systems DAQs and PLCs. The TRS600 is also available with an embedded amplifier with a TEDS / IEEE1451.4 option.

Wide range of applications

The TRS rotary torque sensor series is suited for inline measurement or motor torque applications like electric motor efficiency testing, in line motor torque measurement, industrial robotic automation, monitoring of regenerative braking efficiency (in electric vehicles), fatigue testing of hinges and numerous other laboratory and industrial applications.

Calibration available

A certificate of conformance can be ordered on request. The sensor will be rigorously tested by FUTEK’s world class calibration department whose proprietary and innovative processes exceed the stringent ANSI Z540-1 and ISO 17025 standards. We can also reduce your setup time by calibrating your sensor of choice with an amplifier.

High stiffness and accuracy with non-contact shaft

Description

FUTEK’s Rotary Torque Sensor - Non contact shaft to shaft offers a unique solution for torque auditing applications. The TRS600 Rotary Torque Sensor - Non contact shaft to shaft is available in a wide capacity range and utilizes strain gauge technology. FUTEK's TRS Series is also available with a TEDS / IEEE1451.4 option.

Product Highlights And Features

- Utilizes strain gauge technology

- Compact size

- Can operate up to 12000 RPM (9-89 in-lb)

The TRS600 is a compact shaft-to-shaft rotary torque sensor that provides highly accurate and repeatable measurements in both clockwise and counter clockwise directions. The reactionary shaft allows torque measurements with and without rotation, making it suitable for low and high speed, as well as no speed applications. Some capacities operate at speeds up to 12,000 RPM. Its 7 capacities (which come in different sizes) cover a wide torque range of 1 Nm to 100 Nm. Despite its broad capacity range and high RPM, its compact size range allows for applications with tight spaces. This non-contact rotary torque sensor is an excellent choice for dynamic applications with higher lifespan as it is durable and low maintenance. The design allows for overload protection for up to 150% of the rated output.

Made to be accurate

Due to its high stiffness and low inertia, TRS600 has a nonlinearity of ±0.2% of rated output and is able to maintain accuracy. The high stiffness of the design allows for measurements of dynamic torque changes, including monitoring of intermittent shaft rotations.

Reliable strain gauge technology

TRS600 uses bonded foil strain gauge technology, which offers higher reliability, longer product life, and more immunity to vibrational damages than competing technologies. It also performs well under a wider operational temperature range.

Non-Contact Signal Transfer

Differently from traditional slip rings torque sensors with brushes that make contact with slip rings, TRS600 is equipped with non-contact signal transfer, which increases durability with minimal maintenance.

Low power consumption

The TRS600 has a low power consumption of just 1 W. This is especially valuable for any applications that are battery operated or are embedded in tight spaces where heat generation could become an issue.

Temperature Compensation Capabilities

The TRS600 provides reliable performance over a wide temperature range of –13 to 176°F (–25 to 80°C) and compensates for temperature variation data in the 41 to 122°F (5 to 50°C) range, allowing you to use the sensor in various applications and environments.

Easy installation

Inline shaft-to-shaft design allows for simple and easy installation. The robust 12-pin binder provides the connectivity for signal input and output. The higher capacities feature detachable keys. Please ensure the use of couplings to achieve proper inline positioning.

Flexible connectivity

The TRS600’s outputs can be connected to display devices or other controllers directly. FUTEK provides various cables as well as display devices such as the digital handheld IHH500 or the USB output kit series which can be configured with the sensors. TRS600 is equipped with an embedded signal conditioner, and its output is in amplified ± VDC analog output. Since its output is in VDC amplified range, no additional signal amplification or conditioning is required to support interconnection with Data Acquisition Systems DAQs and PLCs. The TRS600 is also available with an embedded amplifier with a TEDS / IEEE1451.4 option.

Wide range of applications

The TRS rotary torque sensor series is suited for inline measurement or motor torque applications like electric motor efficiency testing, in line motor torque measurement, industrial robotic automation, monitoring of regenerative braking efficiency (in electric vehicles), fatigue testing of hinges and numerous other laboratory and industrial applications.

Calibration available

A certificate of conformance can be ordered on request. The sensor will be rigorously tested by FUTEK’s world class calibration department whose proprietary and innovative processes exceed the stringent ANSI Z540-1 and ISO 17025 standards. We can also reduce your setup time by calibrating your sensor of choice with an amplifier.