Miniature S-Beam Jr.® Load Cell 2.0

Compact, shock resistant, and accurate

Description

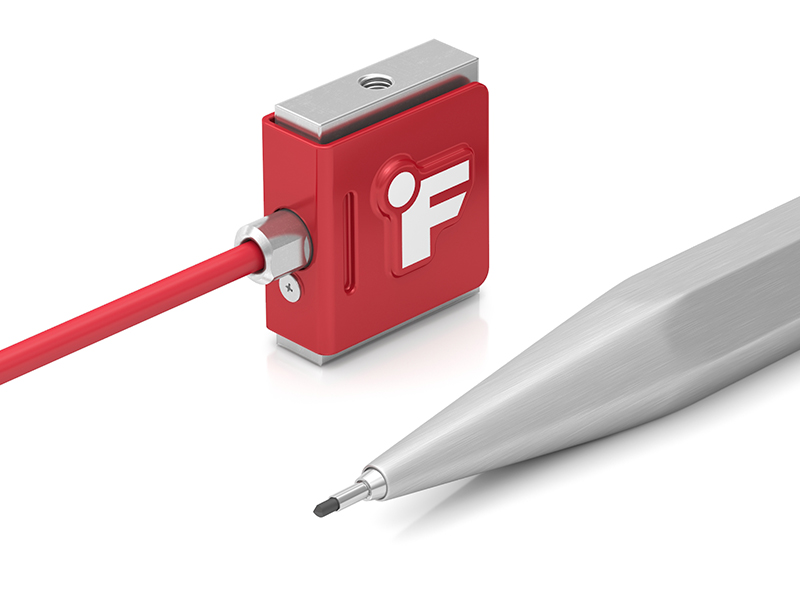

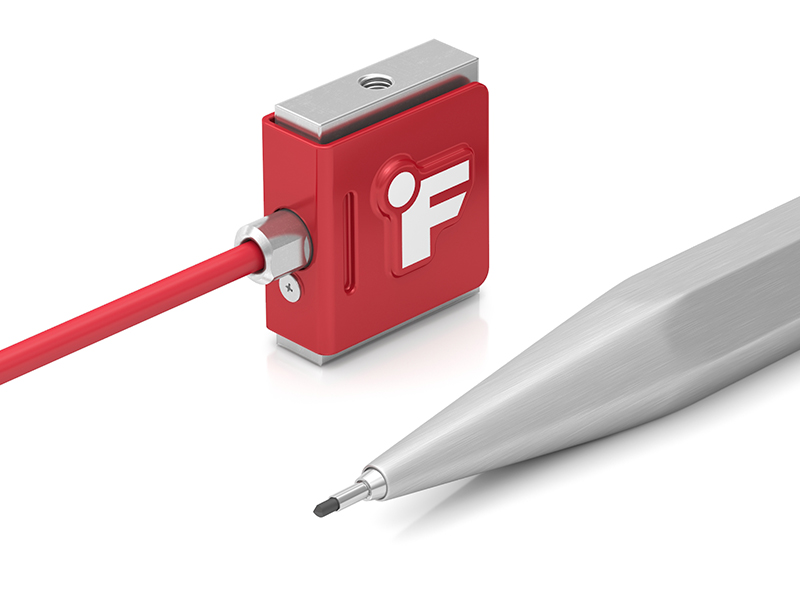

Model LSB201 is a Miniature S Beam Jr.® Load Cell built for Endurance, for Tension, or Compression applications. The standard LSB201 Miniature S Beam Jr.® Load Cell model has a very robust construction available in 17-4 PH Stainless Steel, with female threads on both ends and a 5 feet long 29 AWG 4 conductor Spiral Shielded Silicone Cable. This tension and compression ultra-lightweight micro force sensor offers an exceptional weight of 22 grams only. You will also find a mini load cell for external matched output readily available.

The Miniature Force Sensor offers high accuracy. It has a Nonlinearity of ±0.1% of Rated Output, Deflection of 0.003” nominal, and Safe Overload of up to 1000% of Rated Output. The standard LSB201 Miniature S Beam Jr.® Load Sensor can be modified or customized to meet your requirements and most capacities are in our inventory, making them available for 24-hour shipping. Similar to our entire Load Cell product line this model is manufactured in the USA and uses metal foil strain gauge technology.

Product Highlights And Features

The LSB201 S Beam Jr.® Load Sensor is a high-performing and extremely durable force sensor with a small footprint. Featuring integrated overload protection, shock resistance and available in capacities ranging from 250g to 100lb, this compact and lightweight sensor is ideal for a wide range of dynamic tension and compression applications that require a small footprint, high performance, and accuracy.

This model is also available in versions that have vacuum compatibility, higher IP rating, and high-temperature compensation. LSB201 can also be modified to suit OEM applications. FUTEK offers application and engineering resources during DFM/DFX stage upon request.

Compact package

With dimensions of only 0.75in (H) × 0.3in (W) × 0.65in (L) (19.1mm × 7.6mm × 16.5mm) and a weight of only 0.8oz (22.6g), the highly compact LSB201 sensor can be used in applications where other sensors just won’t fit because of size constraints.

Overload protection

The LSB201 is rated for 10x overload protection for tension and compression (1 to 25lb) and 2x tension overload protection (50 to 100lb). This prevents sensor damage from direct inline overloads that could occur during the setup process or the occasional system overrange.

Highly accurate

The LSB201 delivers a highly accurate performance with a deflection of 0.003in to 0.005in nominal and nonlinearity at 0.1%.

High shock resistance

With an exceptional 500G level shock resistance and 2000Hz vibration resistance, the LSB201 can be used in high shock and high vibration applications such as in drilling, structural monitoring units in earthquake-prone areas, bridges, rail tracks, airplanes, ships, turbines, reactor vessels, and space vehicles.

Peerless durability

Unparalleled quality and robust construction make the LSB201 extremely resilient and long-lasting. The sensor has been tested to +100 million fully reversing fatigue cycles without failure. It has also been designed with a very high level of intrinsic durability for higher system uptime and a significantly longer operational life.

Excellent thermal performance

LSB201 provides reliable performance over a wide temperature range: –60 to 200°F (–50 to 93°C). The excellent thermal performance allows you to use the sensor in various applications and environments.

Flexible cable

The LSB201 sensor is offered with a 29 AWG, 4-conductor, 5-foot (1.5m) long cable with spiral shielding and a silicone outer jacket that offers protection from outer interference. The cable is highly flexible, supporting easy cable management in tight, intricate applications where other cable materials will be problematic.

Best-in-class material

The LSB201 is made from aerospace-grade 17-4 precipitation hardened stainless steel, one of the best material options for load cells. It provides high strength, high hardness, and corrosion resistance over a wide temperature range. A special heat treatment process has been applied to the flexure to improve strength, fatigue properties and sensor performance.

Calibration included

The LSB201 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

Compact, shock resistant, and accurate

Description

Model LSB201 is a Miniature S Beam Jr.® Load Cell built for Endurance, for Tension, or Compression applications. The standard LSB201 Miniature S Beam Jr.® Load Cell model has a very robust construction available in 17-4 PH Stainless Steel, with female threads on both ends and a 5 feet long 29 AWG 4 conductor Spiral Shielded Silicone Cable. This tension and compression ultra-lightweight micro force sensor offers an exceptional weight of 22 grams only. You will also find a mini load cell for external matched output readily available.

The Miniature Force Sensor offers high accuracy. It has a Nonlinearity of ±0.1% of Rated Output, Deflection of 0.003” nominal, and Safe Overload of up to 1000% of Rated Output. The standard LSB201 Miniature S Beam Jr.® Load Sensor can be modified or customized to meet your requirements and most capacities are in our inventory, making them available for 24-hour shipping. Similar to our entire Load Cell product line this model is manufactured in the USA and uses metal foil strain gauge technology.

Product Highlights And Features

The LSB201 S Beam Jr.® Load Sensor is a high-performing and extremely durable force sensor with a small footprint. Featuring integrated overload protection, shock resistance and available in capacities ranging from 250g to 100lb, this compact and lightweight sensor is ideal for a wide range of dynamic tension and compression applications that require a small footprint, high performance, and accuracy.

This model is also available in versions that have vacuum compatibility, higher IP rating, and high-temperature compensation. LSB201 can also be modified to suit OEM applications. FUTEK offers application and engineering resources during DFM/DFX stage upon request.

Compact package

With dimensions of only 0.75in (H) × 0.3in (W) × 0.65in (L) (19.1mm × 7.6mm × 16.5mm) and a weight of only 0.8oz (22.6g), the highly compact LSB201 sensor can be used in applications where other sensors just won’t fit because of size constraints.

Overload protection

The LSB201 is rated for 10x overload protection for tension and compression (1 to 25lb) and 2x tension overload protection (50 to 100lb). This prevents sensor damage from direct inline overloads that could occur during the setup process or the occasional system overrange.

Highly accurate

The LSB201 delivers a highly accurate performance with a deflection of 0.003in to 0.005in nominal and nonlinearity at 0.1%.

High shock resistance

With an exceptional 500G level shock resistance and 2000Hz vibration resistance, the LSB201 can be used in high shock and high vibration applications such as in drilling, structural monitoring units in earthquake-prone areas, bridges, rail tracks, airplanes, ships, turbines, reactor vessels, and space vehicles.

Peerless durability

Unparalleled quality and robust construction make the LSB201 extremely resilient and long-lasting. The sensor has been tested to +100 million fully reversing fatigue cycles without failure. It has also been designed with a very high level of intrinsic durability for higher system uptime and a significantly longer operational life.

Excellent thermal performance

LSB201 provides reliable performance over a wide temperature range: –60 to 200°F (–50 to 93°C). The excellent thermal performance allows you to use the sensor in various applications and environments.

Flexible cable

The LSB201 sensor is offered with a 29 AWG, 4-conductor, 5-foot (1.5m) long cable with spiral shielding and a silicone outer jacket that offers protection from outer interference. The cable is highly flexible, supporting easy cable management in tight, intricate applications where other cable materials will be problematic.

Best-in-class material

The LSB201 is made from aerospace-grade 17-4 precipitation hardened stainless steel, one of the best material options for load cells. It provides high strength, high hardness, and corrosion resistance over a wide temperature range. A special heat treatment process has been applied to the flexure to improve strength, fatigue properties and sensor performance.

Calibration included

The LSB201 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.