Custom Micro Rotary

Transformative miniature that pushes boundaries

Description

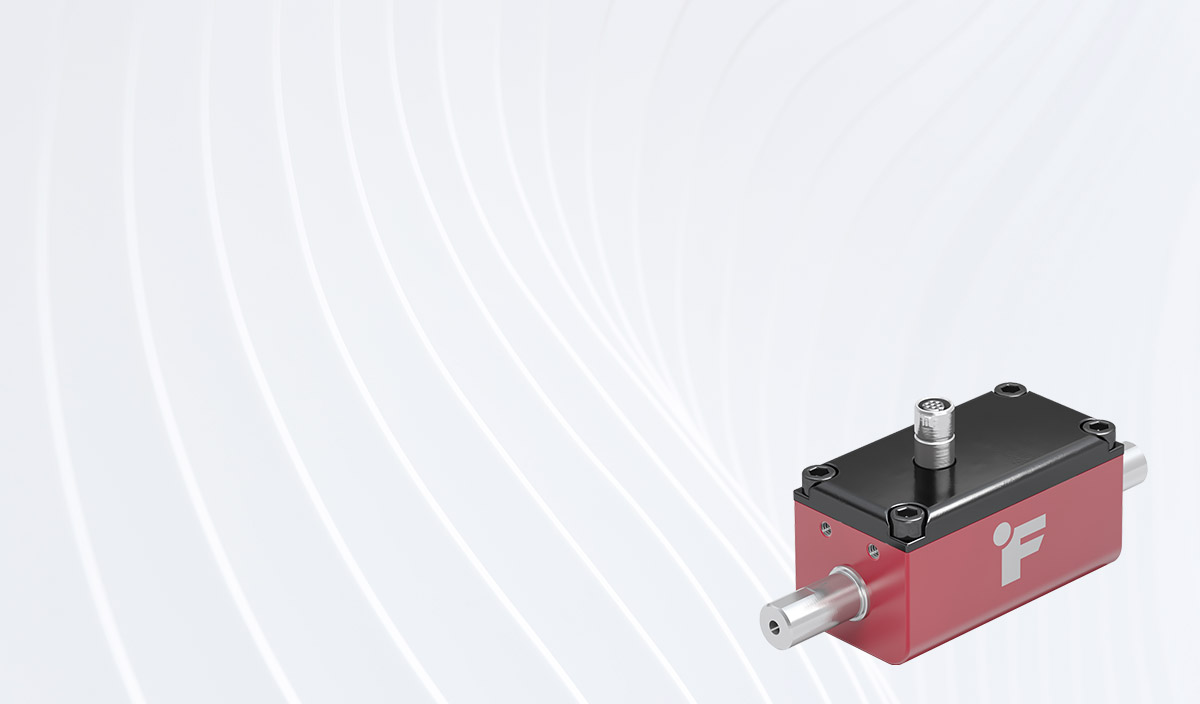

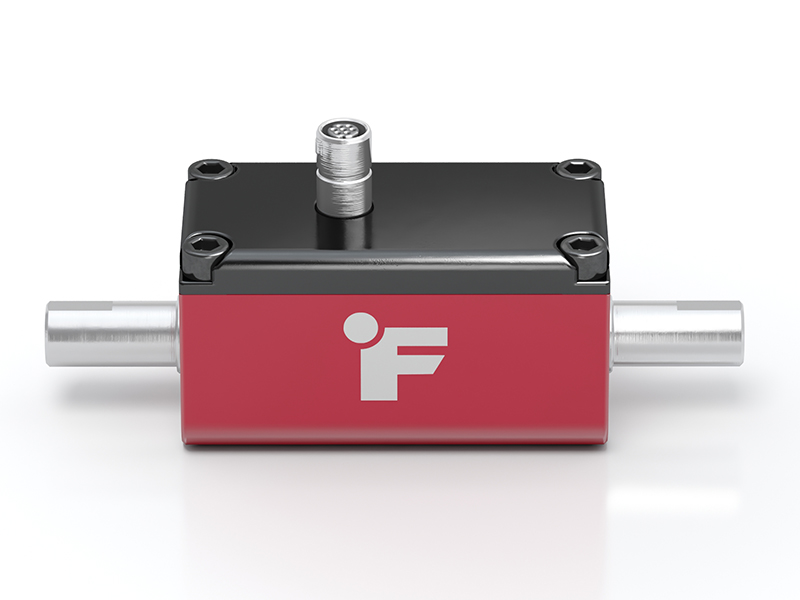

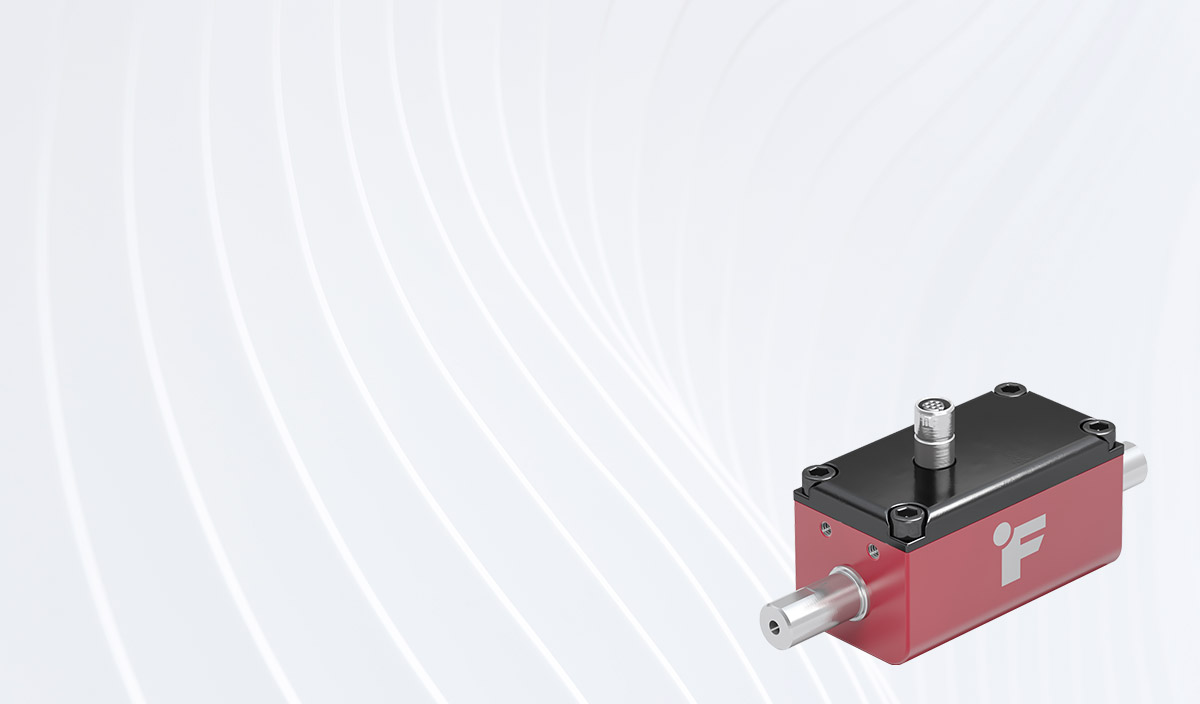

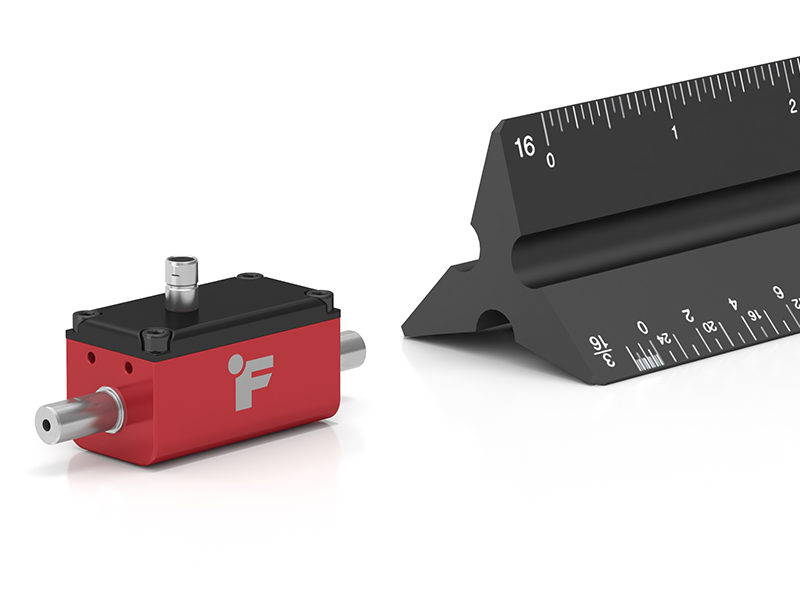

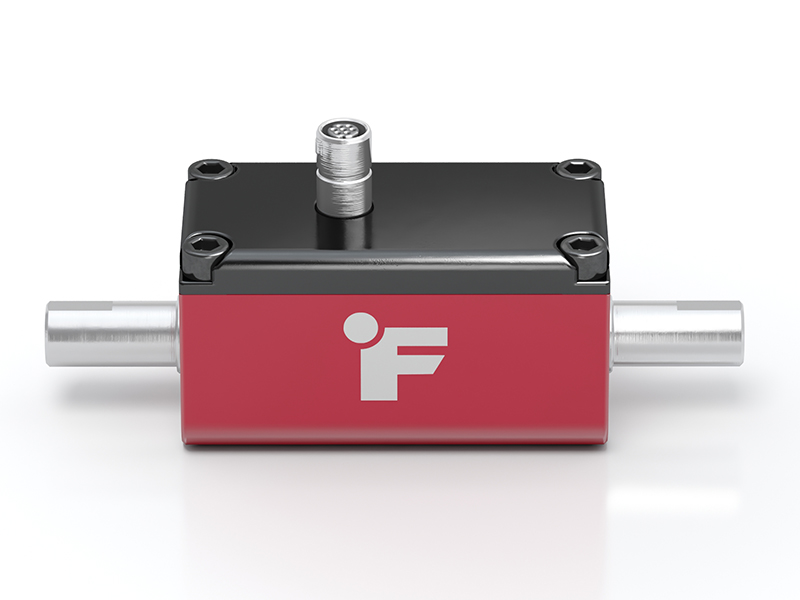

The QTA163 Rotary Torque Sensor is a state-of-the-art, miniature rotary torque sensor designed for space-limited applications where traditional torque measurements have been challenging. With its compact dimensions—0.7 inches by 0.7 inches (17mm x 17mm) cross-section and a length of 2.01 inches (53mm)—the QTA163 is the smallest rotary torque sensor in FUTEK's catalog, offering exceptional performance in space-constrained environments. It features a 5mm male shaft-to-shaft with flats, capable of accurately measuring torque up to 2 Nm in rotational systems operating at speeds up to 150 RPM.

Engineered for precision, the QTA163 boasts impressive performance specifications, including a nonlinearity of ± 0.1% of rated output, hysteresis of ± 0.2% of rated output, and nonrepeatability of ± 0.05% of rated output. These specifications ensure highly reliable and accurate torque measurements, even in demanding applications. The sensor also includes a custom-built slip ring that facilitates precise signal transfer from the rotating shaft to the stationary stator, supported by high-precision machining.

The QTA163 is equipped with a 7-pin quick-disconnect nano receptacle for efficient data transfer to external electronics, enabling real-time readout and control. Additionally, the sensor features integrated TEDS (Transducer Electronic Data Sheet), which simplifies setup and enhances measurement accuracy. TEDS automatically scales the sensor, eliminating common setup errors and offering plug-and-play compatibility. With its robust construction—featuring a 17-4PH stainless steel shaft with flats and aluminum housing, and compliance with RoHS standards—the QTA163 is an indispensable solution for engineers seeking precise and reliable torque measurements in compact, space-limited environments.

Product Highlights And Features

The QTA163 rotary torque sensor is a state-of-the art miniature sensor that pushes technical boundaries in applications where torque measurements have previously not been possible.

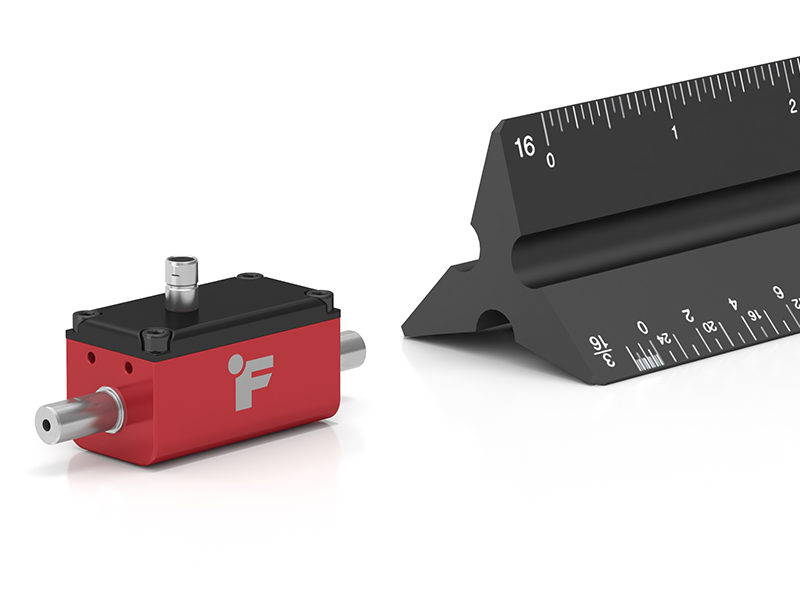

With a 0.7in × 0.7in (17mm × 17mm) cross section and 2.01in (53mm) length, the QTA163 is the smallest rotary torque sensor offered by FUTEK as a catalogue product. It has a 0.2in (5mm) shaft that can measure torque in situations up to 150 rpm.

Small, yet mighty

The super-small size of this sensor allows integration into systems and devices where space is at a premium. The small cross section allows positioning multiple sensors in an array within narrow spaces as compared to stacking larger torque sensors.

Made to be accurate

QTA163 has a custom-built slip ring inside that allows for the electrical signal to transfer from a rotating component to the stationary stator which is outside housing. High precision machining of the components allows for accurate reading and reliability. A standard 7-pin connector allows data transfer to external electronics for readout and control.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, and corrosion resistance over a wide temperature range. The red housing is made of aluminum.

Simple and error-free setup

Incorrect sensor scaling is one of the most common reasons behind erroneous sensor measurements. FUTEK has solved this problem on the QTA163 by equipping it with integrated TEDS as a standard feature. TEDS contains information about the sensor, amplifier setup, sensitivity and reference excitation range. Through auto-scaling, this feature helps to reduce setup errors, and provides for plug and play compatibility.

Calibration included

The QTA163 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Transformative miniature that pushes boundaries

Description

The QTA163 Rotary Torque Sensor is a state-of-the-art, miniature rotary torque sensor designed for space-limited applications where traditional torque measurements have been challenging. With its compact dimensions—0.7 inches by 0.7 inches (17mm x 17mm) cross-section and a length of 2.01 inches (53mm)—the QTA163 is the smallest rotary torque sensor in FUTEK's catalog, offering exceptional performance in space-constrained environments. It features a 5mm male shaft-to-shaft with flats, capable of accurately measuring torque up to 2 Nm in rotational systems operating at speeds up to 150 RPM.

Engineered for precision, the QTA163 boasts impressive performance specifications, including a nonlinearity of ± 0.1% of rated output, hysteresis of ± 0.2% of rated output, and nonrepeatability of ± 0.05% of rated output. These specifications ensure highly reliable and accurate torque measurements, even in demanding applications. The sensor also includes a custom-built slip ring that facilitates precise signal transfer from the rotating shaft to the stationary stator, supported by high-precision machining.

The QTA163 is equipped with a 7-pin quick-disconnect nano receptacle for efficient data transfer to external electronics, enabling real-time readout and control. Additionally, the sensor features integrated TEDS (Transducer Electronic Data Sheet), which simplifies setup and enhances measurement accuracy. TEDS automatically scales the sensor, eliminating common setup errors and offering plug-and-play compatibility. With its robust construction—featuring a 17-4PH stainless steel shaft with flats and aluminum housing, and compliance with RoHS standards—the QTA163 is an indispensable solution for engineers seeking precise and reliable torque measurements in compact, space-limited environments.

Product Highlights And Features

The QTA163 rotary torque sensor is a state-of-the art miniature sensor that pushes technical boundaries in applications where torque measurements have previously not been possible.

With a 0.7in × 0.7in (17mm × 17mm) cross section and 2.01in (53mm) length, the QTA163 is the smallest rotary torque sensor offered by FUTEK as a catalogue product. It has a 0.2in (5mm) shaft that can measure torque in situations up to 150 rpm.

Small, yet mighty

The super-small size of this sensor allows integration into systems and devices where space is at a premium. The small cross section allows positioning multiple sensors in an array within narrow spaces as compared to stacking larger torque sensors.

Made to be accurate

QTA163 has a custom-built slip ring inside that allows for the electrical signal to transfer from a rotating component to the stationary stator which is outside housing. High precision machining of the components allows for accurate reading and reliability. A standard 7-pin connector allows data transfer to external electronics for readout and control.

Best-in-class material

The exceptional quality of this sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, and corrosion resistance over a wide temperature range. The red housing is made of aluminum.

Simple and error-free setup

Incorrect sensor scaling is one of the most common reasons behind erroneous sensor measurements. FUTEK has solved this problem on the QTA163 by equipping it with integrated TEDS as a standard feature. TEDS contains information about the sensor, amplifier setup, sensitivity and reference excitation range. Through auto-scaling, this feature helps to reduce setup errors, and provides for plug and play compatibility.

Calibration included

The QTA163 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.