Universal Pancake Load Cell

Low profile, accurate, and highly resistant to extraneous loads

Description

Model LCF400 is a Pancake Load Cell that has an exceptional one-piece construction flexure design to resist high extraneous loads. The standard LCF400 Pancake Load Cell model has female/female threads, is made of 17-4 Stainless Steel and has a broad capacity ranging from 250 lb to 5,000 lb.

This Pancake Load Cell utilizes metal foil strain gauge technology that offers the highest accuracy. It has Nonlinearity of ±0.10%, Bridge Resistance of 700 Ohms, and Deflection of 0.001" to 0.004” nominal. The standard LCF400 Pancake Load Cell can be modified or customized to meet your requirements and most models are in our inventory making them available for quick delivery.

One of novel applications for this universal pancake load cell its measuring loads in weighing load rigging or lifting applications. Instead of replacing or customizing components, LCF400 pancake load cell can be integrated into the existing load block setup with minimal intervention to the hoisting and load block components. LCF400 with axially mounted rod end bearings is connected to the load block and the hoist hook using the existing shackles and load pins, leaving the existing hoisting elements largely intact. For further info on how LCF400 can be used as a shackle pin load cell, check the application note.

Product Highlights And Features

- Highly resistant to off-axis loading

- One-piece construction

- Utilizes metal foil strain gauge technology

- 17-4 PH stainless-steel construction

- For use in both tension and compression

The LCF400 universal load cell is a highly accurate and versatile low-profile sensor. It features a unique monolithic multi-beam flexure design that offers outstanding resistance to high extraneous loads as well as exceptionally low deflection and non-linearity and very fast dynamic response.

Measuring both tension and compression loads, the LCF400 is ideal for inline applications with limited vertical space that require a sensor that has the ability to handle eccentric or extraneous loads and still maintain a high level of accuracy and reliability.

It's available in a wide range of capacities from 250 to 5000lb (113 to 2268kg). The unit can operate in the temperature range of –65 to 200°F (–54 to 93°C) and features M12x1.75 metric male/female threads for attachment. Typical applications include continuous load monitoring as well as car dyno testing, whose long performance cycles demand reliable performance. As an upgraded option, the LCF400 is available in a version that features TEDS auto-recognition of calibration data and dual/redundant bridge.

Short and compact

At 2in (50.8mm) height and 3.48in (88.4mm) diameter, the sensor is small enough to fit into most applications without a major redesign of the equipment. The flexure design features an integrated baseplate that reduces the sensor's height, making it particularly compact compared to traditional pancake style sensors.

Highly accurate

The proprietary multi-beam design features a fully machined unit with multiple spokes and connecting rods that are carved out from a single block of alloy. Coupled with FUTEK’s sophisticated metal foil strain gauge technology this feature guarantees high accuracy.

Resists high extraneous loads

The internal design structure with its high stiff flexure provides low deflection and low sensitivity, as well as accurate measurements to off-axis loads, even in high extraneous load conditions. Extraneous loads are resisted by the multibeam design, where two sets of four beams, arranged in a unique offset, work together to reject extraneous forces.

Best-in-class material

The exceptional quality of FUTEK’s LCF400 sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, and corrosion resistance over a wide temperature range. The laser-welded design helps improve robustness in harsh environments and allows for an IP64 rating.

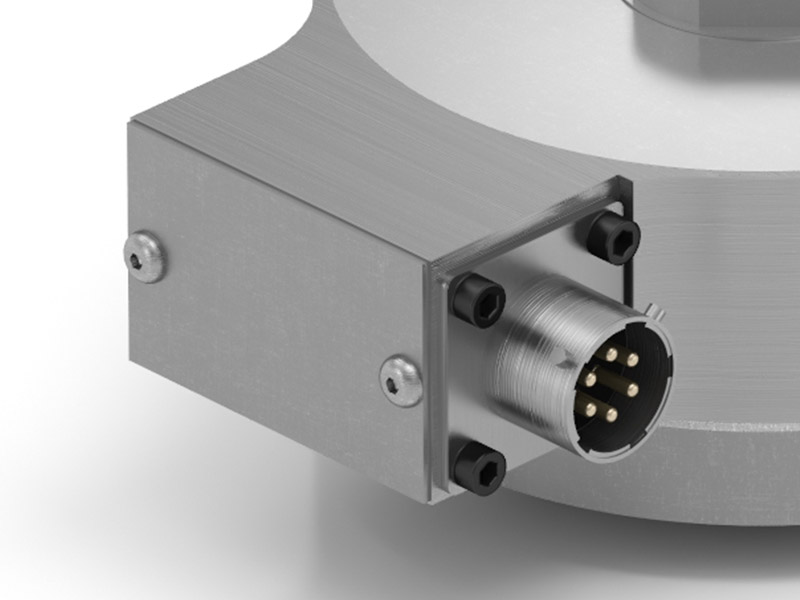

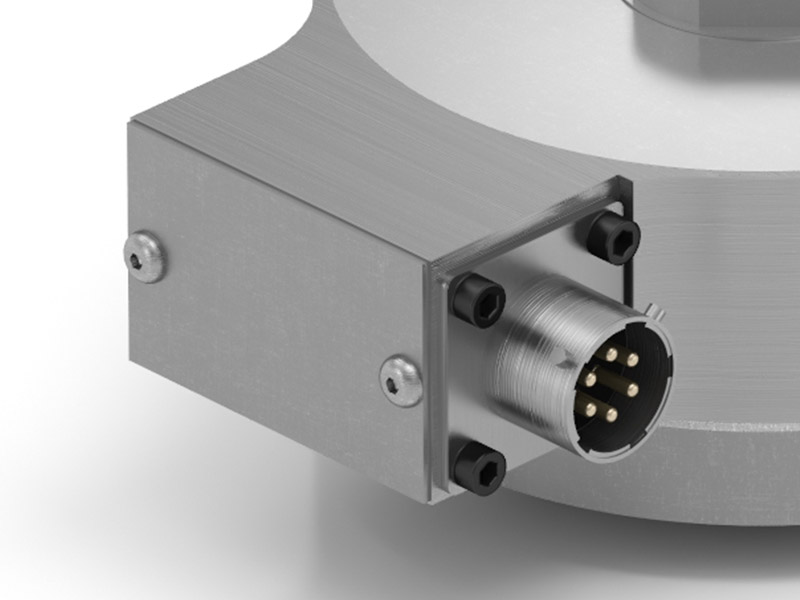

Plug in, plug out

The LCF400 is available with a 6-pin Bendix connector that allows for easy and simple cable connection and disconnection. A damaged sensor cable can be replaced without having to replace or disassemble the sensor or any other system component, which saves time, leads to higher system availability and reduces total cost of ownership.

Dynamic response ready

The high natural frequency of the sensors, ranging from 2600Hz to 7700Hz, offers faster dynamic response, suited for continuous load monitoring applications for challenging applications. In bulk material handling, the source container and the collecting unit can both benefit from use of these sensors, reducing material transfer time and improving throughput without sacrificing accuracy.

Simple and error-free setup

As an optional feature, the LCF400 is now available with IEEE 1451.4 TEDS. TEDS contains information about the sensor, amplifier setup, sensitivity and reference excitation range. Through auto-scaling, this feature helps to reduce setup errors, and provides for plug and play compatibility with FUTEK instruments like digital load cell and handheld displays.

Versatile applications

FUTEK’s LCF series sensors are well suited for applications such as torque sensing, engine dyno testing, package drop test unit, force measurement in workout equipment, material force testing, portable crane weighing, crane lifting, tank and hopper weighing systems, dual tank level controllers, silo weight monitoring, automated container filling, medical patient lifts, tank dispensers, shackle pin load cells, injection moulding force feedback systems and prosthetic hip fatigue testing. LCF400 can be customized for dual bridge, low outgassing, vacuum rated, cryogenic and water-resistant applications.

Calibration included

The LCF400 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

Low profile, accurate, and highly resistant to extraneous loads

Description

Model LCF400 is a Pancake Load Cell that has an exceptional one-piece construction flexure design to resist high extraneous loads. The standard LCF400 Pancake Load Cell model has female/female threads, is made of 17-4 Stainless Steel and has a broad capacity ranging from 250 lb to 5,000 lb.

This Pancake Load Cell utilizes metal foil strain gauge technology that offers the highest accuracy. It has Nonlinearity of ±0.10%, Bridge Resistance of 700 Ohms, and Deflection of 0.001" to 0.004” nominal. The standard LCF400 Pancake Load Cell can be modified or customized to meet your requirements and most models are in our inventory making them available for quick delivery.

One of novel applications for this universal pancake load cell its measuring loads in weighing load rigging or lifting applications. Instead of replacing or customizing components, LCF400 pancake load cell can be integrated into the existing load block setup with minimal intervention to the hoisting and load block components. LCF400 with axially mounted rod end bearings is connected to the load block and the hoist hook using the existing shackles and load pins, leaving the existing hoisting elements largely intact. For further info on how LCF400 can be used as a shackle pin load cell, check the application note.

Product Highlights And Features

- Highly resistant to off-axis loading

- One-piece construction

- Utilizes metal foil strain gauge technology

- 17-4 PH stainless-steel construction

- For use in both tension and compression

The LCF400 universal load cell is a highly accurate and versatile low-profile sensor. It features a unique monolithic multi-beam flexure design that offers outstanding resistance to high extraneous loads as well as exceptionally low deflection and non-linearity and very fast dynamic response.

Measuring both tension and compression loads, the LCF400 is ideal for inline applications with limited vertical space that require a sensor that has the ability to handle eccentric or extraneous loads and still maintain a high level of accuracy and reliability.

It's available in a wide range of capacities from 250 to 5000lb (113 to 2268kg). The unit can operate in the temperature range of –65 to 200°F (–54 to 93°C) and features M12x1.75 metric male/female threads for attachment. Typical applications include continuous load monitoring as well as car dyno testing, whose long performance cycles demand reliable performance. As an upgraded option, the LCF400 is available in a version that features TEDS auto-recognition of calibration data and dual/redundant bridge.

Short and compact

At 2in (50.8mm) height and 3.48in (88.4mm) diameter, the sensor is small enough to fit into most applications without a major redesign of the equipment. The flexure design features an integrated baseplate that reduces the sensor's height, making it particularly compact compared to traditional pancake style sensors.

Highly accurate

The proprietary multi-beam design features a fully machined unit with multiple spokes and connecting rods that are carved out from a single block of alloy. Coupled with FUTEK’s sophisticated metal foil strain gauge technology this feature guarantees high accuracy.

Resists high extraneous loads

The internal design structure with its high stiff flexure provides low deflection and low sensitivity, as well as accurate measurements to off-axis loads, even in high extraneous load conditions. Extraneous loads are resisted by the multibeam design, where two sets of four beams, arranged in a unique offset, work together to reject extraneous forces.

Best-in-class material

The exceptional quality of FUTEK’s LCF400 sensor makes it highly durable and reliable. Its body is made of aerospace-grade 17-4 precipitation hardened stainless steel, which provides high strength, high hardness, and corrosion resistance over a wide temperature range. The laser-welded design helps improve robustness in harsh environments and allows for an IP64 rating.

Plug in, plug out

The LCF400 is available with a 6-pin Bendix connector that allows for easy and simple cable connection and disconnection. A damaged sensor cable can be replaced without having to replace or disassemble the sensor or any other system component, which saves time, leads to higher system availability and reduces total cost of ownership.

Dynamic response ready

The high natural frequency of the sensors, ranging from 2600Hz to 7700Hz, offers faster dynamic response, suited for continuous load monitoring applications for challenging applications. In bulk material handling, the source container and the collecting unit can both benefit from use of these sensors, reducing material transfer time and improving throughput without sacrificing accuracy.

Simple and error-free setup

As an optional feature, the LCF400 is now available with IEEE 1451.4 TEDS. TEDS contains information about the sensor, amplifier setup, sensitivity and reference excitation range. Through auto-scaling, this feature helps to reduce setup errors, and provides for plug and play compatibility with FUTEK instruments like digital load cell and handheld displays.

Versatile applications

FUTEK’s LCF series sensors are well suited for applications such as torque sensing, engine dyno testing, package drop test unit, force measurement in workout equipment, material force testing, portable crane weighing, crane lifting, tank and hopper weighing systems, dual tank level controllers, silo weight monitoring, automated container filling, medical patient lifts, tank dispensers, shackle pin load cells, injection moulding force feedback systems and prosthetic hip fatigue testing. LCF400 can be customized for dual bridge, low outgassing, vacuum rated, cryogenic and water-resistant applications.

Calibration included

The LCF400 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.