Miniature S-Beam Jr.® Load Cell 2.0

Maximum power, miniature package

Description

- Integrated IEEE1451.4 TEDs chip makes setup simple and greatly reduces setup errors. Connects directly to electronics and auto-scales to FUTEK instruments and signal conditioners.

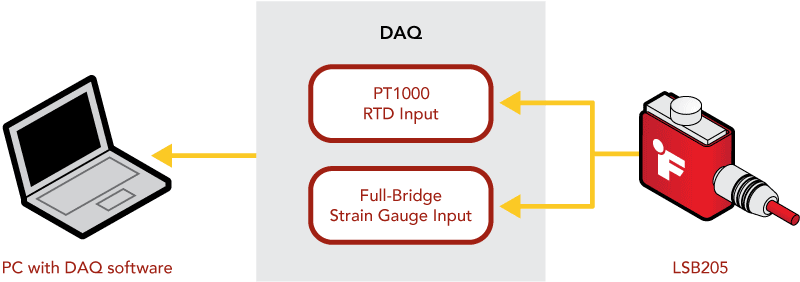

- PT1000 temperature sensor enables support for real-time temperature compensation, ensuring accuracy in different environments.

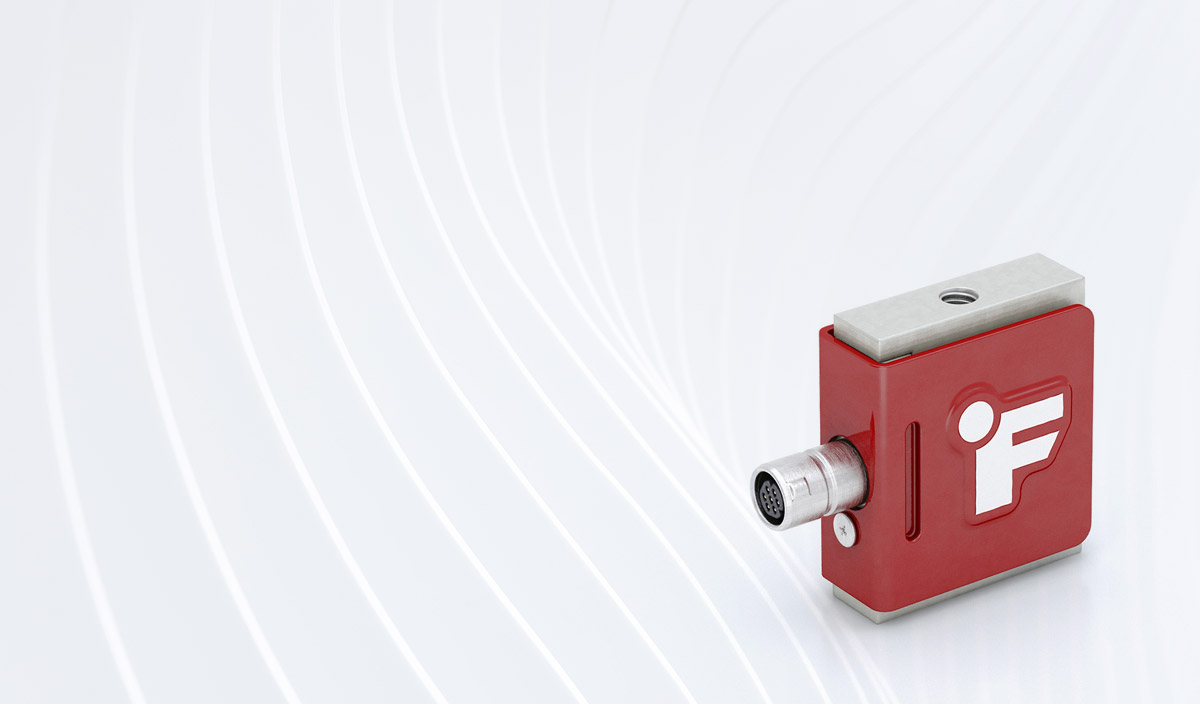

- Detachable 7 Pin FUTEK aerospace-grade cable connector allows for quick cable disconnect and helps separate the force sensor from cable damage

Product Highlights And Features

- Size: 0.75” x 0.69” x 0.26”

- Force measurement capacity: 250g to 100 lbs.

- Fatigue-rated for 100 million cycles.

- Optimized design to withstand extraneous load limits

- New generation design with increased natural frequency

- Integrated 1000% of RO overload protection for safe installment.

- Robust case design and heat-treated, aerospace-grade stainless steel optimizes durability, linearity, and off-center loading capabilities.

- Exceptional non-repeatability (±0.05% of RO).

- Highly shock and vibration-resistant (500G), performs exceedingly well in high-vibration environments.

The LSB205 S Beam Jr.® Load Sensor is one of FUTEK’s most in-demand miniature force sensors, offering exceptional accuracy, unparalleled capabilities, and best-in-class durability in a tiny package. Built for both tension and compression applications, this versatile model is perfect for any application that requires high accuracy and a small footprint. It offers a wide load measurement range of 8 capacities from 250g to 100lb. Integrated features such as TEDS, PT1000 temperature sensor and a military-grade connector ensure accuracy and make setup headache and error-free.

OEM versions without the outer cover are also available with integrated FPC style connectors. A vacuum compatible version is offered for chamber testing applications or space/flight rated uses. Threads are metric.

Compact package

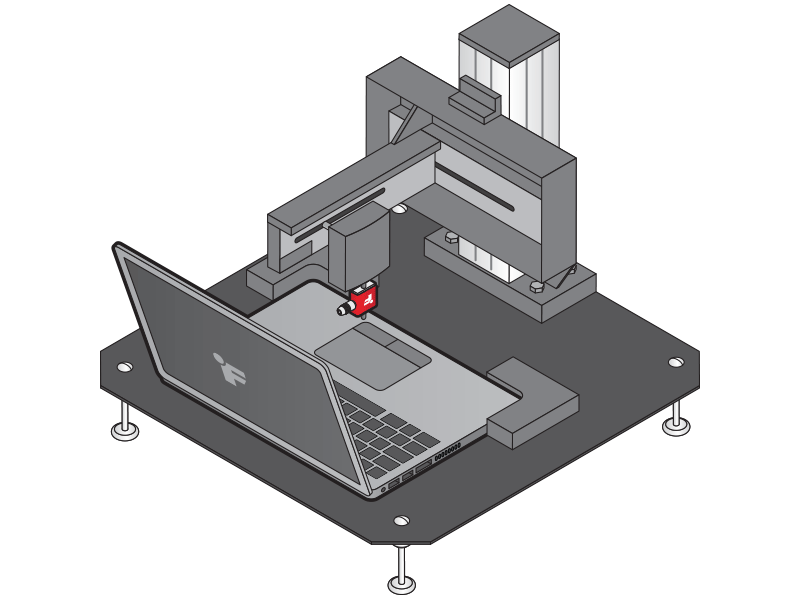

With dimensions of only 0.75in × 0.3in × 0.65in (19.05mm × 7.6mm × 16.5mm) (excluding the connector) and a weight of only 3oz (9g), the highly compact LSB205 sensor can be used in applications where other sensors just won’t fit because of size constraints.

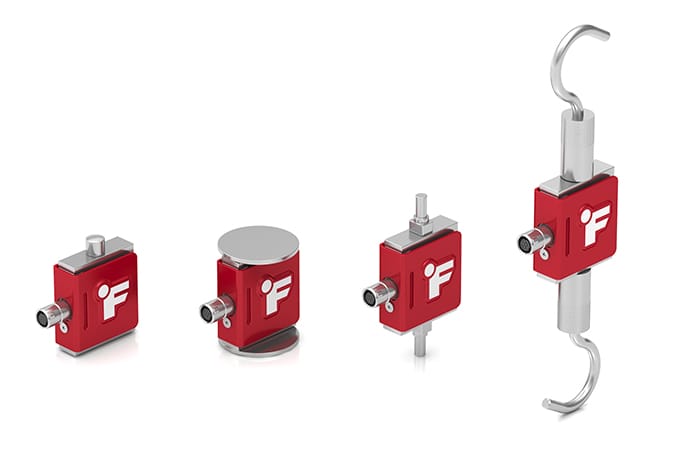

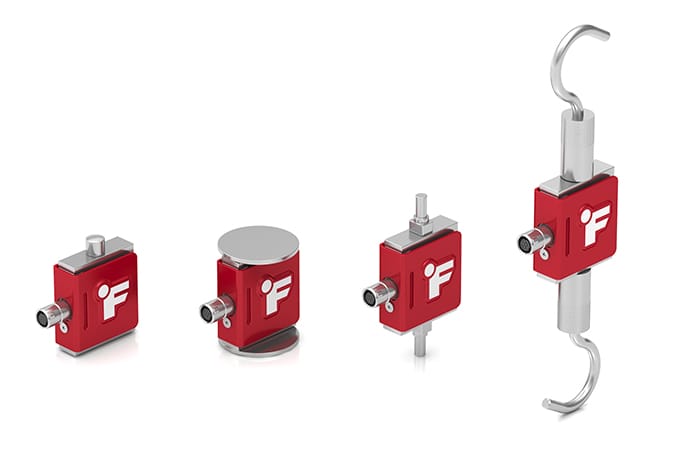

Versatile mounting

The LSB205 features two M3 x 0.5 female threads that make mounting fast and easy. The unit can also be installed in a variety of ways with a wide range of accessories depending on the requirements of the application.

Peerless durability

Unparalleled quality and robust construction make the LSB205 extremely resilient and long-lasting. The sensor has been tested to +100 million fully reversing fatigue cycles without failure. It has also been designed with a very high level of intrinsic durability for higher system uptime and a significantly longer operational life.

High-volume, tight-fitting OEM applications

LSB205 is also available in a version that was designed for high-volume OEM applications. Featuring the same accuracy and capabilities as the standard version, this cover-less unit saves space in tight-fitting assemblies and has a board mount 7-position FPC connector that allows for easy board-to-board electrical connections.

Overload protection

The LSB205 is rated for 10x overload protection for tension and compression (1 to 25lb) and 2x tension overload protection (50 to 100lb). This prevents sensor damage from direct inline overloads that could occur during setup process or the occasional system overrange.

High shock resistance

With an exceptional 500G level shock resistance and 2000Hz vibration resistance, the LSB205 can be used in high shock and high vibration applications such as in drilling, structural monitoring units in earthquake prone areas, bridges, rail tracks, airplanes, ships, turbines, reactor vessels, and space vehicles.

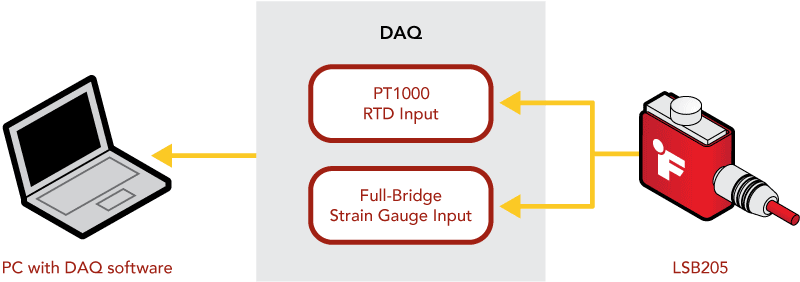

Integrated temperature sensor

An integrated PT1000 RTD temperature sensor supports active temperature compensation to obtain highly accurate sensor load values. This feature allows the monitoring of interior temperature and is especially useful for environments that either have a high rate of temperature change or temperature change across a wide range of values.

Plug in, plug out

The LSB205 sensor comes with an aerospace- and military-grade 7-pin nano connector that allows for easy and simple cable connection and disconnection. A damaged sensor cable can be replaced without having to replace or disassemble the LSB205 sensor or any other system component, which saves time, leads to higher system availability, and reduces total cost of ownership. It also simplifies the installation process, reducing installation time and maximizing up-time, and allows different sensor cables to be swapped out for integration with multiple instruments.

Best-in-class material

The LSB205 is made from aerospace-grade 17-4 precipitation hardened stainless steel, one of the best material options for load cells. It provides high strength, high hardness, and corrosion resistance over a wide temperature range. It also enhances this tiny sensor’s ability to handle extraneous forces.

Calibration included

The LSB205 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

Maximum power, miniature package

Description

- Integrated IEEE1451.4 TEDs chip makes setup simple and greatly reduces setup errors. Connects directly to electronics and auto-scales to FUTEK instruments and signal conditioners.

- PT1000 temperature sensor enables support for real-time temperature compensation, ensuring accuracy in different environments.

- Detachable 7 Pin FUTEK aerospace-grade cable connector allows for quick cable disconnect and helps separate the force sensor from cable damage

Product Highlights And Features

- Size: 0.75” x 0.69” x 0.26”

- Force measurement capacity: 250g to 100 lbs.

- Fatigue-rated for 100 million cycles.

- Optimized design to withstand extraneous load limits

- New generation design with increased natural frequency

- Integrated 1000% of RO overload protection for safe installment.

- Robust case design and heat-treated, aerospace-grade stainless steel optimizes durability, linearity, and off-center loading capabilities.

- Exceptional non-repeatability (±0.05% of RO).

- Highly shock and vibration-resistant (500G), performs exceedingly well in high-vibration environments.

The LSB205 S Beam Jr.® Load Sensor is one of FUTEK’s most in-demand miniature force sensors, offering exceptional accuracy, unparalleled capabilities, and best-in-class durability in a tiny package. Built for both tension and compression applications, this versatile model is perfect for any application that requires high accuracy and a small footprint. It offers a wide load measurement range of 8 capacities from 250g to 100lb. Integrated features such as TEDS, PT1000 temperature sensor and a military-grade connector ensure accuracy and make setup headache and error-free.

OEM versions without the outer cover are also available with integrated FPC style connectors. A vacuum compatible version is offered for chamber testing applications or space/flight rated uses. Threads are metric.

Compact package

With dimensions of only 0.75in × 0.3in × 0.65in (19.05mm × 7.6mm × 16.5mm) (excluding the connector) and a weight of only 3oz (9g), the highly compact LSB205 sensor can be used in applications where other sensors just won’t fit because of size constraints.

Versatile mounting

The LSB205 features two M3 x 0.5 female threads that make mounting fast and easy. The unit can also be installed in a variety of ways with a wide range of accessories depending on the requirements of the application.

Peerless durability

Unparalleled quality and robust construction make the LSB205 extremely resilient and long-lasting. The sensor has been tested to +100 million fully reversing fatigue cycles without failure. It has also been designed with a very high level of intrinsic durability for higher system uptime and a significantly longer operational life.

High-volume, tight-fitting OEM applications

LSB205 is also available in a version that was designed for high-volume OEM applications. Featuring the same accuracy and capabilities as the standard version, this cover-less unit saves space in tight-fitting assemblies and has a board mount 7-position FPC connector that allows for easy board-to-board electrical connections.

Overload protection

The LSB205 is rated for 10x overload protection for tension and compression (1 to 25lb) and 2x tension overload protection (50 to 100lb). This prevents sensor damage from direct inline overloads that could occur during setup process or the occasional system overrange.

High shock resistance

With an exceptional 500G level shock resistance and 2000Hz vibration resistance, the LSB205 can be used in high shock and high vibration applications such as in drilling, structural monitoring units in earthquake prone areas, bridges, rail tracks, airplanes, ships, turbines, reactor vessels, and space vehicles.

Integrated temperature sensor

An integrated PT1000 RTD temperature sensor supports active temperature compensation to obtain highly accurate sensor load values. This feature allows the monitoring of interior temperature and is especially useful for environments that either have a high rate of temperature change or temperature change across a wide range of values.

Plug in, plug out

The LSB205 sensor comes with an aerospace- and military-grade 7-pin nano connector that allows for easy and simple cable connection and disconnection. A damaged sensor cable can be replaced without having to replace or disassemble the LSB205 sensor or any other system component, which saves time, leads to higher system availability, and reduces total cost of ownership. It also simplifies the installation process, reducing installation time and maximizing up-time, and allows different sensor cables to be swapped out for integration with multiple instruments.

Best-in-class material

The LSB205 is made from aerospace-grade 17-4 precipitation hardened stainless steel, one of the best material options for load cells. It provides high strength, high hardness, and corrosion resistance over a wide temperature range. It also enhances this tiny sensor’s ability to handle extraneous forces.

Calibration included

The LSB205 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.