OEM Load Cell

Lightweight, compact with incomparable accuracy

Description

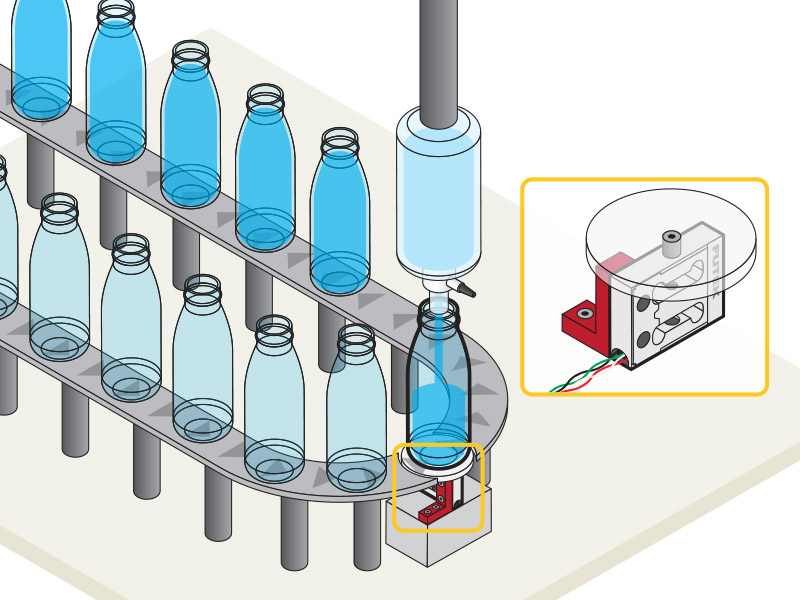

The LSM300 High Precision Load Cell also known as the Belt Buckle Load Cell offers an impressive lightweight design with an easy side mounting feature making it ideal for OEM applications such as weight measurement solution for automatic bottle filling machines.

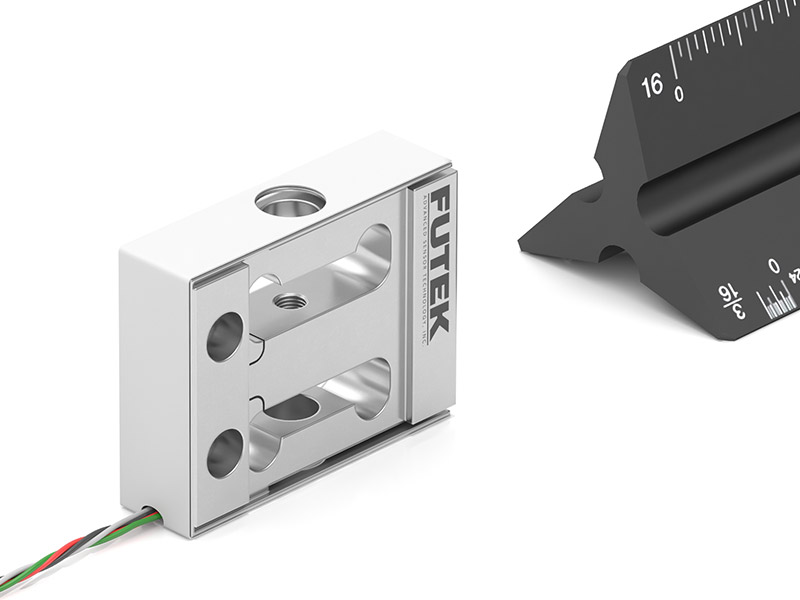

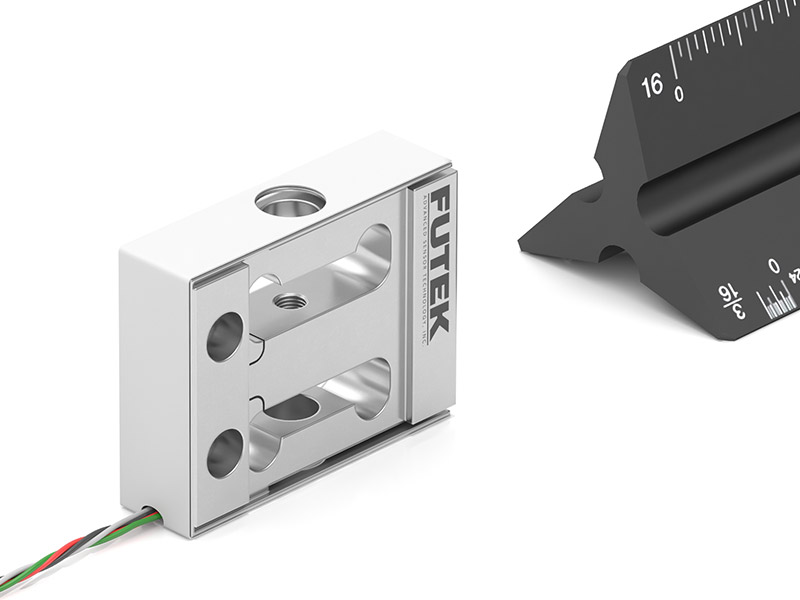

Utilized in both Tension and Compression, the LSM300 High Accuracy Load Cell has a length of 1.80”, width of 0.50” and with a height of 1.40” it is well suited for any tight spaces.

Additional design features includes a built in overload protection providing the unit over 10 times the capacity that could take place during installation. As a part of FUTEK’s original product line, the High Accuracy Load Cell can be modified or customized to meet your requirements and most standard capacities are available in our inventory, making it available for 24 hour shipping.

Product Highlights And Features

- High Accuracy Load Cell

- Intended for high volume applications

- Easily integrates into OEM applications such as automatic bottle filling machines

- Built-in overload protection

- Exceptional nonlinearity and nonrepeatability

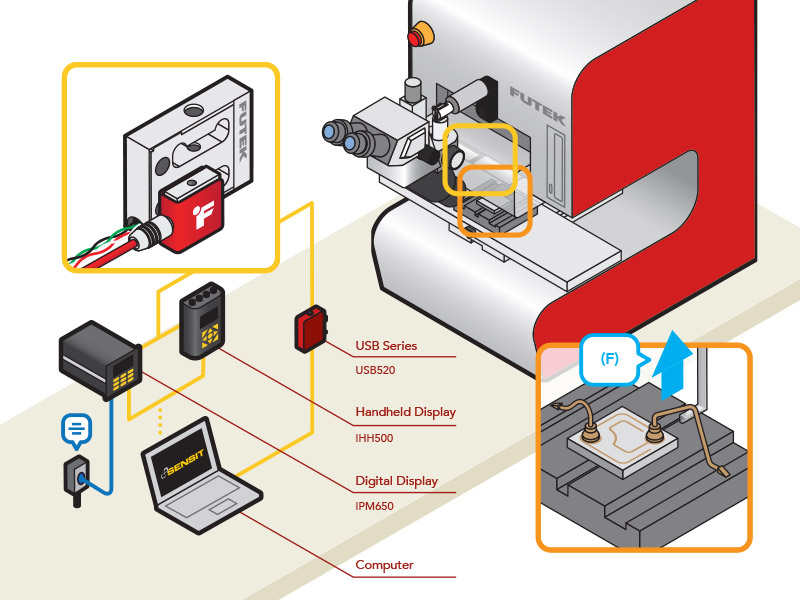

- Can integrate with analog VDC, mA, digital SPI, I2C, RS-232, UART output, and more

The compact and lightweight LSM300 has the distinction of being the most accurate load cell in FUTEK’s catalog of high precision sensors. Designed for easy integration into OEM tension and compression applications, this sensor, which is also known as a belt buckle load cell, has a unique design that gives the unit its high accuracy and reliability.

Two versatile mounting provisions —side mounting at one end and single point mounting in the centre of the unit — offers easy and flexible integration. The unit has a built-in overload protection and can operate in a wide temperature range of –60 to 200°F (–50 to 93°C). It has a wide capacity range of 2.2 to 200lb.

LSM300 is ideal for high volume continuous usage and typical applications include bottle filling, syringe calibration, and industrial measurements.

Impressive light-weight design

At 1.8in (45.7mm) length, 1.4in (34.8mm) width and 0.5in (12.7mm) thickness, the LSM300 is specifically targeted for OEM applications that require space saving design. Made of light-weight aluminum alloy, the sensor itself weighs only 28g for all models except FSH03980 which is rated for 90Kg capacity (85g, made of stainless steel).

Ideal for OEM applications

LSM series of sensors are built for OEM applications, as the model eliminates all exterior components like cover or casing and even cable jackets and connector pins in order to reduce the footprint as much as possible. While the LSM300 is more robust than most OEM sensors due to a protective cover that prevents mechanical damage, it still requires white-glove handling during installation and set-up.

Exceptional non-linearity

The 2.2lb to 100lb capacities of the LSM300 provide the lowest nonlinearity (0.02%) and non-repeatability (0.02%) offered by any FUTEK sensor. (The 200lb capacity has a non-linearity of 0.06%, which is still remarkably low.) The parallelogram structure allows the beam design to convert the load into high strain, which is monitored by the metal foil strain gauge.

Low power consumption

With a 1000 Ohm bridge resistance, the LSM300 consumes less current than a traditional sensor. This is especially valuable for any applications that are battery operated or are embedded in tight spaces where heat generation could become an issue.

Excellent thermal performance

The LSM350 provides reliable performance over a wide temperature range of –60 to 200°F (–50 to 93°C) allowing you to use the sensor in various applications and environments.

Integrated overload protection

The unique overload stop design, (250lb safe overload for 2.2 to 100lb capacities and 400lb safe overload for 200lb capacities), protects the sensor from damage during accidental overload in both tension and compression modes. It also decreases the risk of mechanical breakage and yield as the overload stop helps to stop the part from deflecting, which prevents the metal from going into its yield state.

Freedom to customize

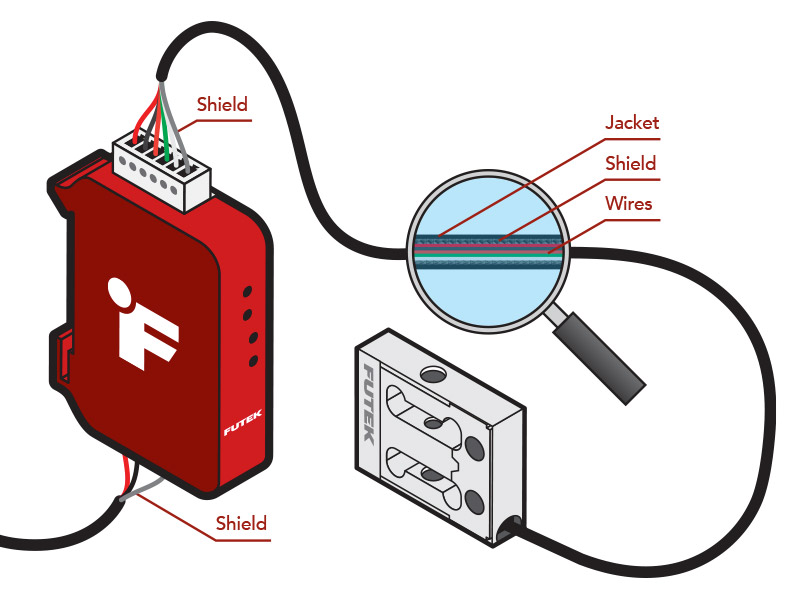

LSM300 model sensors can be customized easily. FCI female crimp connectors can be added to the spiral Teflon cable, which in turn can be replaced by a spiral shielded silicone cable. As all aluminum models have the same thread size and the same mounting, two capacities can easily be swapped if the product weighing range increases or decreases.

Robust construction

Most LSM300 sensor models are built with aerospace grade aluminum alloy AL2024-T4, which is known for its high strength, durability, and corrosion resistance. The 200lb rated model is built with 17-4 precipitation hardened stainless steel. A Valox cover protects the sensor from damage of the strain gage and wires during installation.

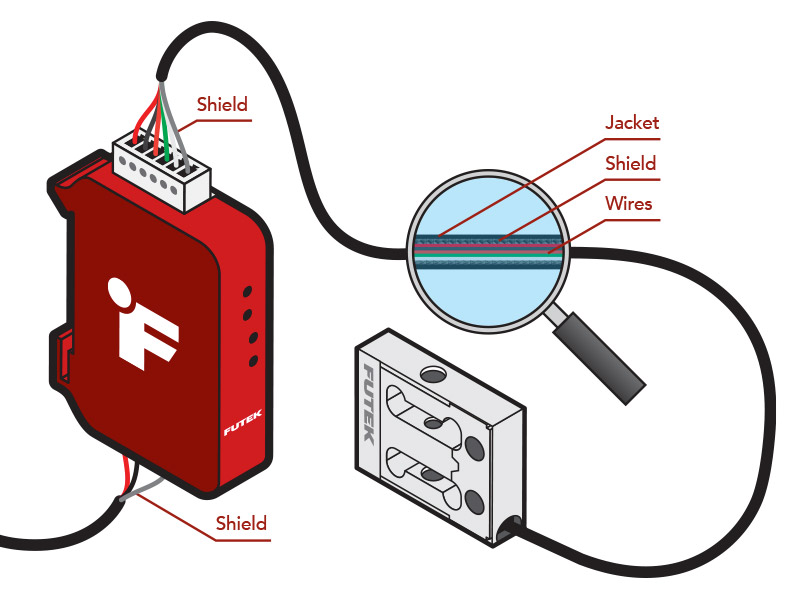

Cable integration

All standard LSM300 models are offered with a standard 4-conductor spiral Teflon cable that allows data collection. The load cell can be paired with signal conditioners, amplifiers and indicators for specific OEM applications and interfaced quickly to your existing equipment.

High volume, high accuracy

The LSM300 model is aimed squarely at high volume, high accuracy measurements. Applications cover a very wide range of markets, such as syringe calibration, wire bond testing (in micro-electronics), medical tablet and pill weighing and capsule filling, food processing, batching systems, small scales, check-weighing systems, batching scales, counting scales, and mass flow meters.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

Lightweight, compact with incomparable accuracy

Description

The LSM300 High Precision Load Cell also known as the Belt Buckle Load Cell offers an impressive lightweight design with an easy side mounting feature making it ideal for OEM applications such as weight measurement solution for automatic bottle filling machines.

Utilized in both Tension and Compression, the LSM300 High Accuracy Load Cell has a length of 1.80”, width of 0.50” and with a height of 1.40” it is well suited for any tight spaces.

Additional design features includes a built in overload protection providing the unit over 10 times the capacity that could take place during installation. As a part of FUTEK’s original product line, the High Accuracy Load Cell can be modified or customized to meet your requirements and most standard capacities are available in our inventory, making it available for 24 hour shipping.

Product Highlights And Features

- High Accuracy Load Cell

- Intended for high volume applications

- Easily integrates into OEM applications such as automatic bottle filling machines

- Built-in overload protection

- Exceptional nonlinearity and nonrepeatability

- Can integrate with analog VDC, mA, digital SPI, I2C, RS-232, UART output, and more

The compact and lightweight LSM300 has the distinction of being the most accurate load cell in FUTEK’s catalog of high precision sensors. Designed for easy integration into OEM tension and compression applications, this sensor, which is also known as a belt buckle load cell, has a unique design that gives the unit its high accuracy and reliability.

Two versatile mounting provisions —side mounting at one end and single point mounting in the centre of the unit — offers easy and flexible integration. The unit has a built-in overload protection and can operate in a wide temperature range of –60 to 200°F (–50 to 93°C). It has a wide capacity range of 2.2 to 200lb.

LSM300 is ideal for high volume continuous usage and typical applications include bottle filling, syringe calibration, and industrial measurements.

Impressive light-weight design

At 1.8in (45.7mm) length, 1.4in (34.8mm) width and 0.5in (12.7mm) thickness, the LSM300 is specifically targeted for OEM applications that require space saving design. Made of light-weight aluminum alloy, the sensor itself weighs only 28g for all models except FSH03980 which is rated for 90Kg capacity (85g, made of stainless steel).

Ideal for OEM applications

LSM series of sensors are built for OEM applications, as the model eliminates all exterior components like cover or casing and even cable jackets and connector pins in order to reduce the footprint as much as possible. While the LSM300 is more robust than most OEM sensors due to a protective cover that prevents mechanical damage, it still requires white-glove handling during installation and set-up.

Exceptional non-linearity

The 2.2lb to 100lb capacities of the LSM300 provide the lowest nonlinearity (0.02%) and non-repeatability (0.02%) offered by any FUTEK sensor. (The 200lb capacity has a non-linearity of 0.06%, which is still remarkably low.) The parallelogram structure allows the beam design to convert the load into high strain, which is monitored by the metal foil strain gauge.

Low power consumption

With a 1000 Ohm bridge resistance, the LSM300 consumes less current than a traditional sensor. This is especially valuable for any applications that are battery operated or are embedded in tight spaces where heat generation could become an issue.

Excellent thermal performance

The LSM350 provides reliable performance over a wide temperature range of –60 to 200°F (–50 to 93°C) allowing you to use the sensor in various applications and environments.

Integrated overload protection

The unique overload stop design, (250lb safe overload for 2.2 to 100lb capacities and 400lb safe overload for 200lb capacities), protects the sensor from damage during accidental overload in both tension and compression modes. It also decreases the risk of mechanical breakage and yield as the overload stop helps to stop the part from deflecting, which prevents the metal from going into its yield state.

Freedom to customize

LSM300 model sensors can be customized easily. FCI female crimp connectors can be added to the spiral Teflon cable, which in turn can be replaced by a spiral shielded silicone cable. As all aluminum models have the same thread size and the same mounting, two capacities can easily be swapped if the product weighing range increases or decreases.

Robust construction

Most LSM300 sensor models are built with aerospace grade aluminum alloy AL2024-T4, which is known for its high strength, durability, and corrosion resistance. The 200lb rated model is built with 17-4 precipitation hardened stainless steel. A Valox cover protects the sensor from damage of the strain gage and wires during installation.

Cable integration

All standard LSM300 models are offered with a standard 4-conductor spiral Teflon cable that allows data collection. The load cell can be paired with signal conditioners, amplifiers and indicators for specific OEM applications and interfaced quickly to your existing equipment.

High volume, high accuracy

The LSM300 model is aimed squarely at high volume, high accuracy measurements. Applications cover a very wide range of markets, such as syringe calibration, wire bond testing (in micro-electronics), medical tablet and pill weighing and capsule filling, food processing, batching systems, small scales, check-weighing systems, batching scales, counting scales, and mass flow meters.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.