Micro Parallelogram

Low-profile space- and power-saver with flexible wall mounting

Description

Product Highlights And Features

One of the smallest sensors in the FUTEK catalogue, the miniature wall mount sensor LSM100 is a micro parallelogram load cell that stands out because of its extremely low profile, greater output, low power consumption, and overload protection without compromising performance.

The unit can be used in both tension and compression modes. It has a low height of 0.25in (6.4mm), a load capacity of 450g, and a built-in 10X overload protection. The delicate strain gauge instrumentation is placed only on the top side, and there are two mounting provisions at the non-loading end.

LSM100 is designed for high volume continuous usage and can be easily integrated into OEM applications. Typical applications include medical weighing and industrial measurements.

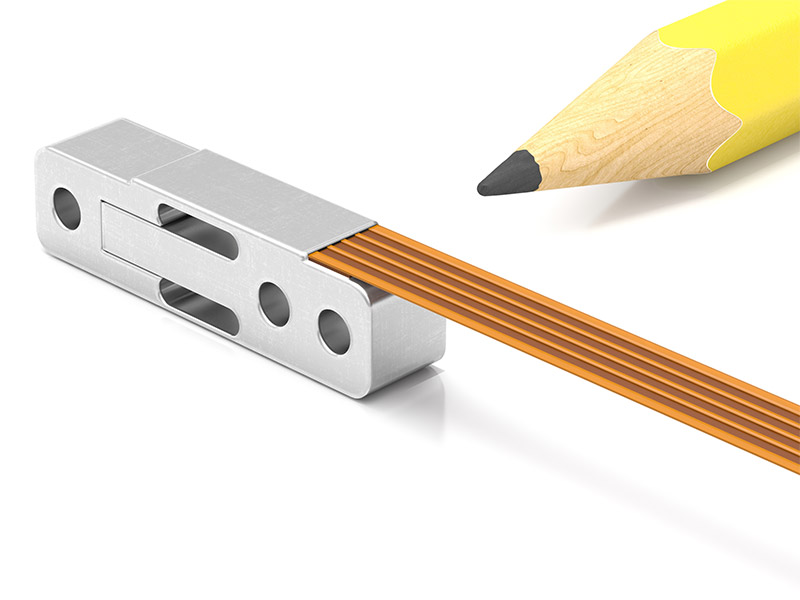

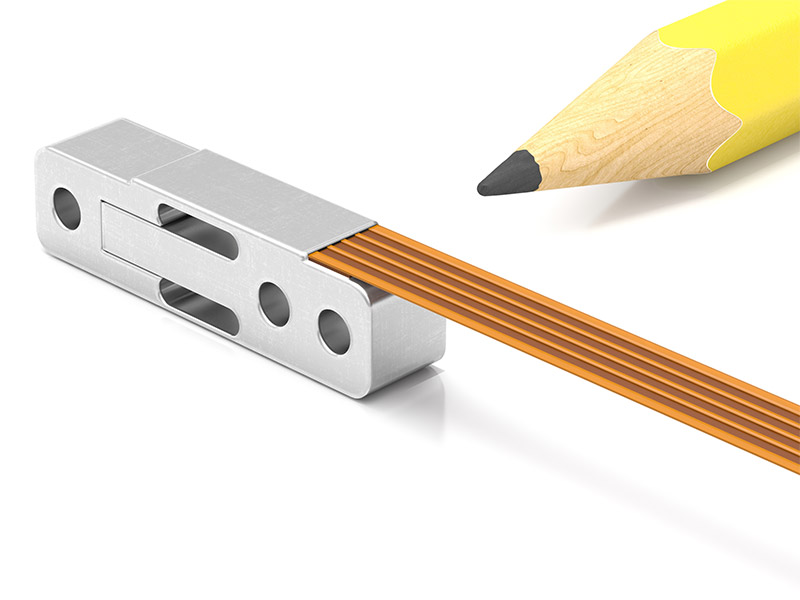

Small but mighty

Measuring 0.25in (6.4mm) tall and 0.22in (5.4mm) wide, LSM100 is specifically targeted for applications which require ultra-small footprints. The extremely light-weight sensor weighs only 2.3 grams. The sensor can accept up to a 10V excitation, which allows for 30 mV output to be available for its paired electronics.

Aerospace grade material

LSM100 is built with aerospace grade aluminium alloy AL2024-T4, which is known for its high strength, durability, corrosion resistance as well as its low hysteresis effect along with minimal creep over time. The material and design also ensures exceptional nonlinearity (0.05%) and non-repeatability (0.05%).

High accuracy

FUTEK’s proprietary parallelogram structure allows the cantilever beam design to convert the load into high strain, which is monitored by the metal foil strain gauge. The resulting current feedback can be converted to load data, ensuring the user both accurate and reliable measurements with high sensitivity.

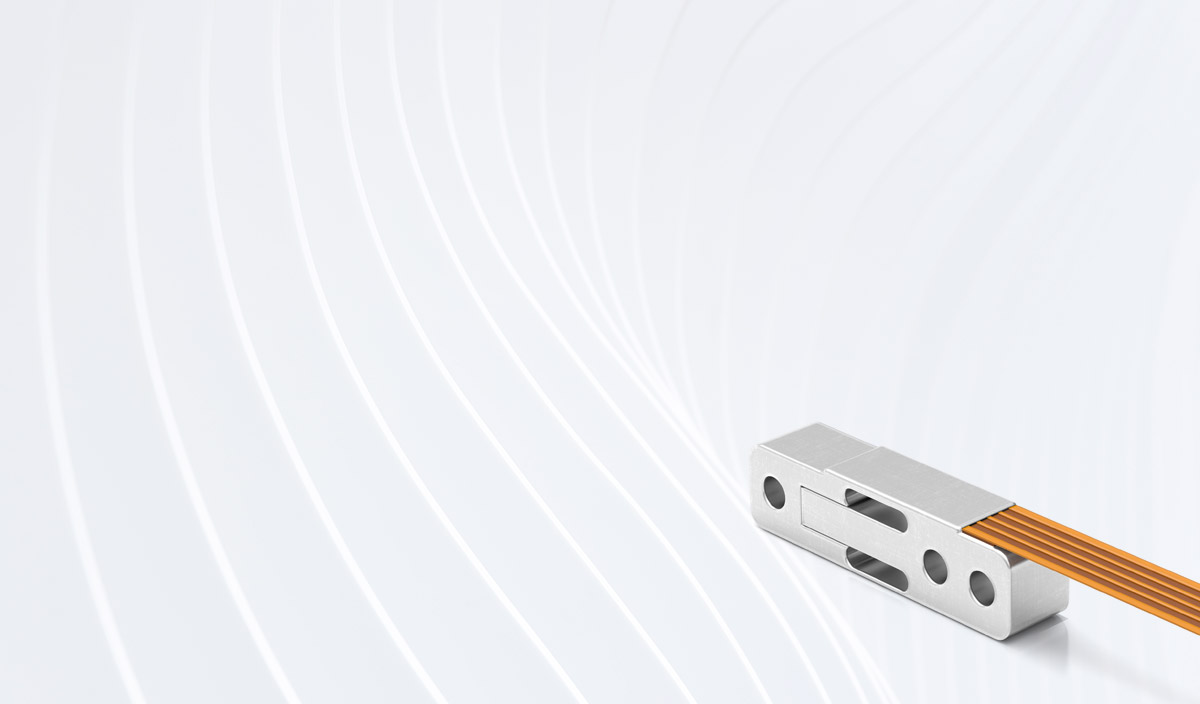

Unique mounting provisions

Even though the LSM100 has an exceedingly low profile, it still features loading provisions, enabling the user to add their own mounting surface, allowing them to make the most out of their space and lowering assembly cost. The dual mounting provision at the fixed end ensures that the sensor is locked in place securely, avoiding noise and vibrations during measurement.

Built-in overload protection

An integrated overload stop design protects the sensor from damage during accidental overload. It also decreases the risk of mechanical breakage and yield as the overload stop helps to stop the part from deflecting, which prevents the metal from going into its yield state.

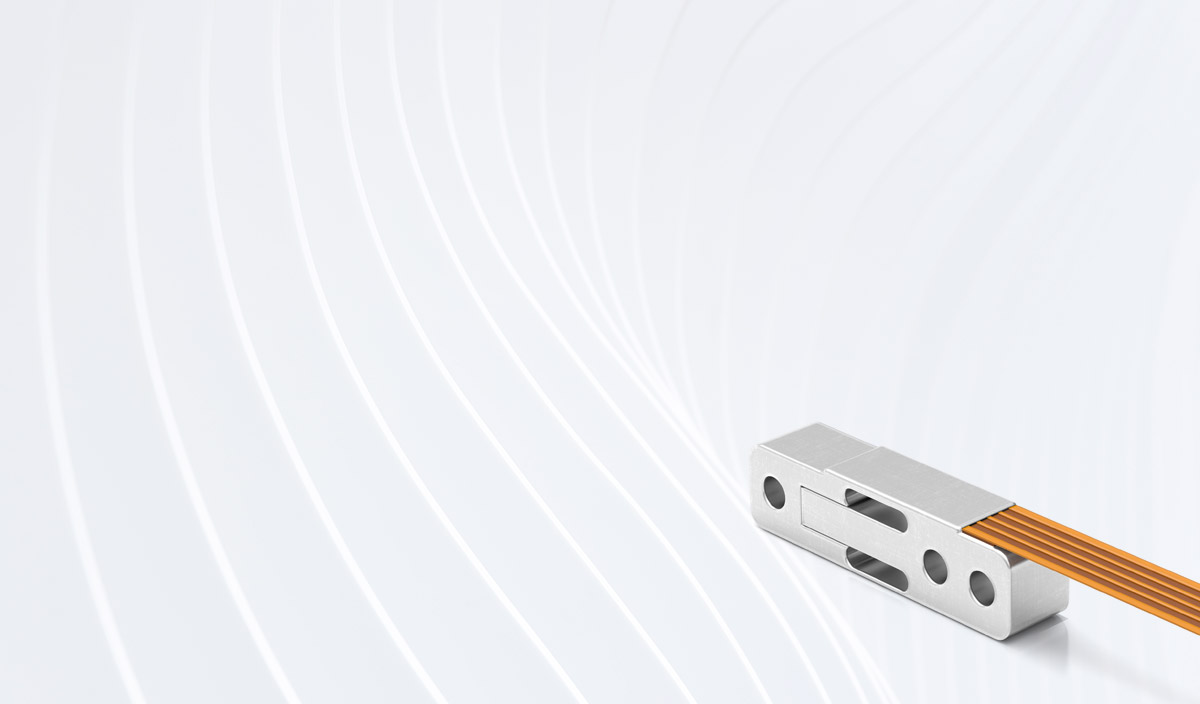

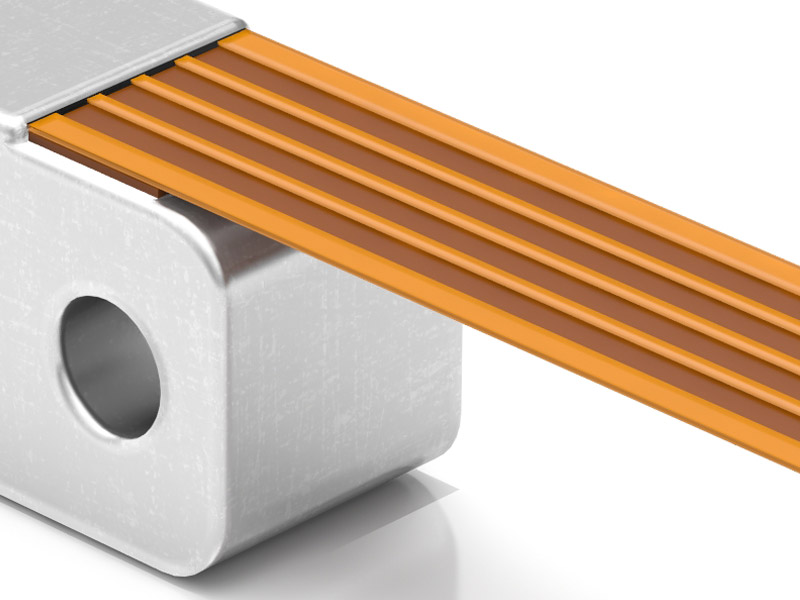

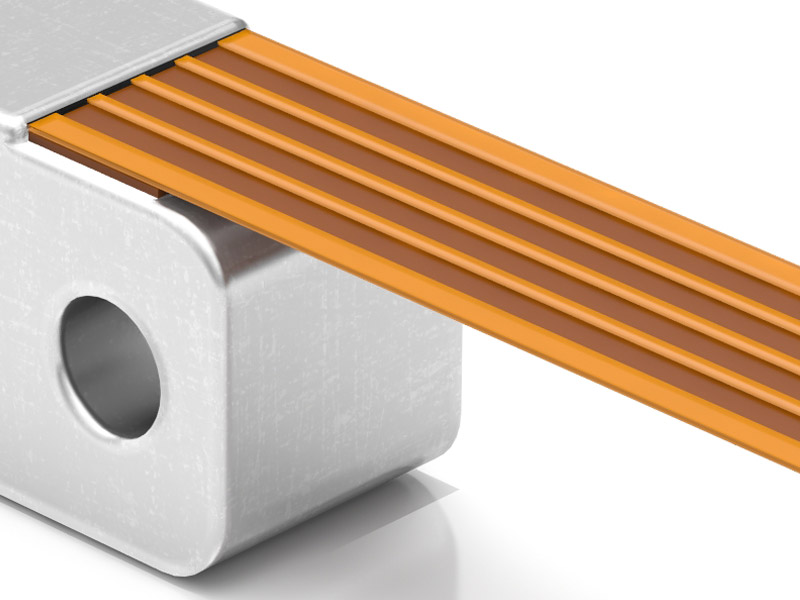

Flexible connectivity

The LSM100 is offered with a standard 4-pin flex connector and a 4-position 1mm pitch flexible circuit cable for direct connection to onboard connectors, allowing data collection through two excitation input pins and two signal output pins. The unit is rated for 3mV/V feedback, allowing a max output of 30mV on a 10V input.

Diverse applications

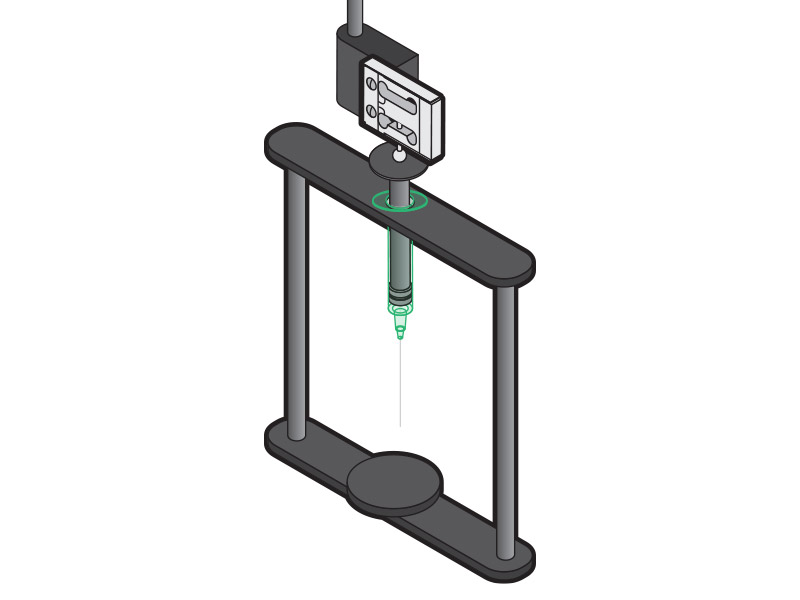

FUTEK’s LSM series sensors are widely used in applications such as syringe calibration, wire bond testing (in micro-electronics), medical tablet and pill weighing and capsule filling, food processing, batching systems, small scales, check-weighing systems, batching scales, counting scales, and mass flow meters. It can also operate in a wide range of temperatures, from -60°F to 200°F.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.

Low-profile space- and power-saver with flexible wall mounting

Description

Product Highlights And Features

One of the smallest sensors in the FUTEK catalogue, the miniature wall mount sensor LSM100 is a micro parallelogram load cell that stands out because of its extremely low profile, greater output, low power consumption, and overload protection without compromising performance.

The unit can be used in both tension and compression modes. It has a low height of 0.25in (6.4mm), a load capacity of 450g, and a built-in 10X overload protection. The delicate strain gauge instrumentation is placed only on the top side, and there are two mounting provisions at the non-loading end.

LSM100 is designed for high volume continuous usage and can be easily integrated into OEM applications. Typical applications include medical weighing and industrial measurements.

Small but mighty

Measuring 0.25in (6.4mm) tall and 0.22in (5.4mm) wide, LSM100 is specifically targeted for applications which require ultra-small footprints. The extremely light-weight sensor weighs only 2.3 grams. The sensor can accept up to a 10V excitation, which allows for 30 mV output to be available for its paired electronics.

Aerospace grade material

LSM100 is built with aerospace grade aluminium alloy AL2024-T4, which is known for its high strength, durability, corrosion resistance as well as its low hysteresis effect along with minimal creep over time. The material and design also ensures exceptional nonlinearity (0.05%) and non-repeatability (0.05%).

High accuracy

FUTEK’s proprietary parallelogram structure allows the cantilever beam design to convert the load into high strain, which is monitored by the metal foil strain gauge. The resulting current feedback can be converted to load data, ensuring the user both accurate and reliable measurements with high sensitivity.

Unique mounting provisions

Even though the LSM100 has an exceedingly low profile, it still features loading provisions, enabling the user to add their own mounting surface, allowing them to make the most out of their space and lowering assembly cost. The dual mounting provision at the fixed end ensures that the sensor is locked in place securely, avoiding noise and vibrations during measurement.

Built-in overload protection

An integrated overload stop design protects the sensor from damage during accidental overload. It also decreases the risk of mechanical breakage and yield as the overload stop helps to stop the part from deflecting, which prevents the metal from going into its yield state.

Flexible connectivity

The LSM100 is offered with a standard 4-pin flex connector and a 4-position 1mm pitch flexible circuit cable for direct connection to onboard connectors, allowing data collection through two excitation input pins and two signal output pins. The unit is rated for 3mV/V feedback, allowing a max output of 30mV on a 10V input.

Diverse applications

FUTEK’s LSM series sensors are widely used in applications such as syringe calibration, wire bond testing (in micro-electronics), medical tablet and pill weighing and capsule filling, food processing, batching systems, small scales, check-weighing systems, batching scales, counting scales, and mass flow meters. It can also operate in a wide range of temperatures, from -60°F to 200°F.

Made in Irvine, CA

Designed and manufactured in-house. Our multidisciplinary engineering teams, high precision machining center, state-of-the-art quality assurance systems, and R&D and manufacturing facilities are all under one roof, allowing us to continuously reinvent and refine our products and processes.