Custom Autoclavable Load Button Load Cell

Autoclavable and unstoppable

Description

QLA402 Custom Autoclavable Load Button Loadcell

Product Highlights And Features

Standing at 0.53in (13.5mm) × 0.16in (4mm) the QLA402 is a miniature, low profile, sterilizable, load button load cell with an extraordinarily robust monolithic design. Based on our patented (#US10527509B2) hermetic sealing technology, this high-quality sensor can withstand the harsh physical and chemical conditions in the autoclave and survive over a thousand cycles while providing consistent performance, providing a long service life, low maintenance, and low replacement costs while reducing material waste and cost per procedure.

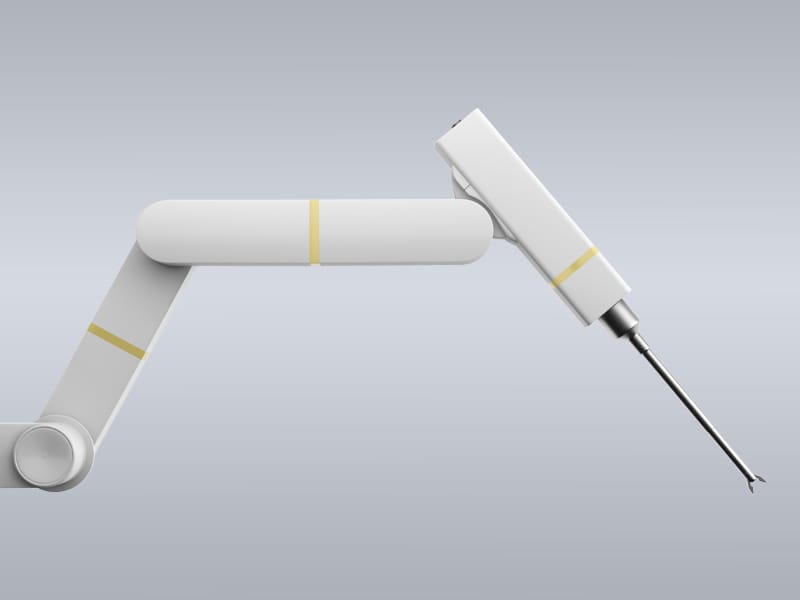

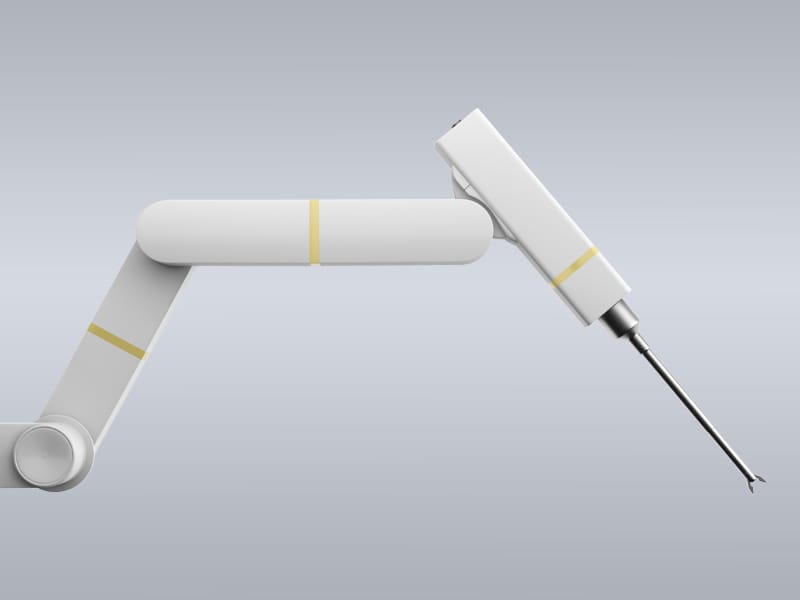

Its small size and autoclavability offers incomparable value for advanced handheld medical tools that require haptic feedback capabilities as close to the surgical site as possible. This model can also be modified to suit OEM applications. FUTEK offers application and engineering resources during DFM/DFX stage upon request.

Designed for autoclave applications

The FUTEK QLA402 sensor is ideal for autoclave applications, such as smart laparoscopic and endoscopic tools. Its patented design was made to withstand harsh conditions such as high-pressure steam sterilization and operate reliably in environments with high temperature and pressure steam, bleach, and other high pH liquids. Other than autoclaves, the QLA402 is suitable for other critical areas such as aerospace and harsh industrial applications.

Patented hermetic sealing

QLA402 load cell employs the FUTEK’s patented, monolithic hermetically sealed design, which results in a robust, air-tight, and waterproof device suitable for unique and custom force-sensing requirements. Hermetically sealing the load cells protects the devices from the ingress of steam, liquids, and other particles in the autoclave, and especially at elevated temperatures and pressures.

Highest protection rating

Due to the patented technology, the QLA402 has an IP69K-rating, the highest protection against ingress of dust, liquids, and steam jets, meaning that it can withstand almost any harsh condition as well as over a thousand autoclave sterilization cycles

Miniature monolithic design

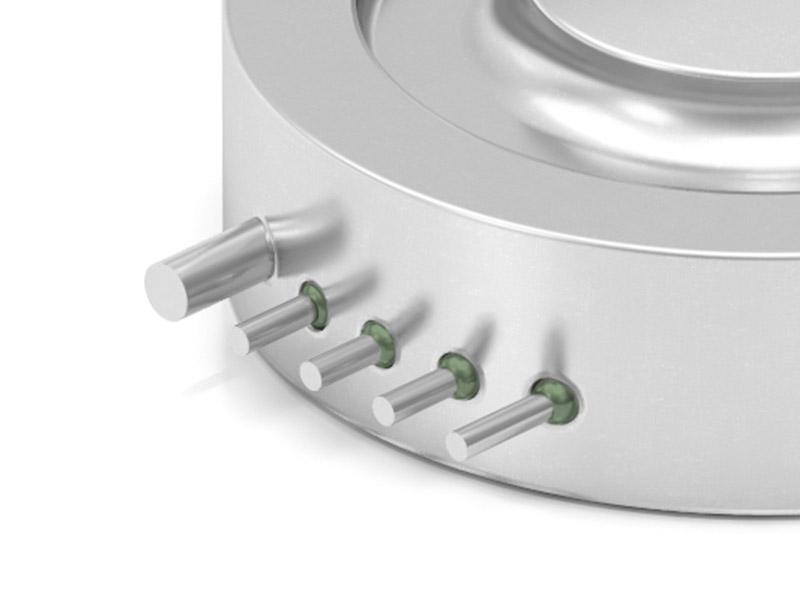

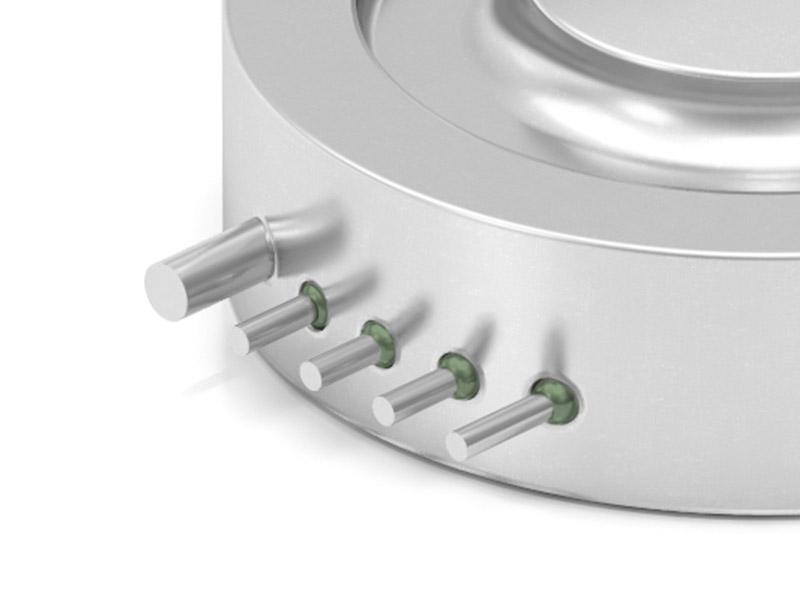

The QLA402 has a unique monolithic design that features protruding connector pins that have been hermetically sealed using a proprietary no-welding process, making the sensor very durable and capable of withstanding extremely harsh conditions. This technology also shrinks the package size, allowing the sensor to have its exceedingly low profile.

Flexible connection

Unlike the traditional load sensor with integrated cable, the FUTEK QLA402 has a connector output that increases flexibility and maintainability. The sensor has an integrated hermetically sealed pin header, with pins that protrude from the housing to provide easy-to-access electrical power and signal connections. This design provides connection flexibility, as users can directly solder wires or flex circuits onto the pin headers.

Powerful material

The QLA402 body has an excellent corrosion-resistant Inconel alloy body. The construction material is suitable for almost any fluid and has a high resistance to scaling and oxalic acid effects. Its outstanding oxidation and corrosion resistance at elevated temperatures makes the load cell ideal for harsh autoclave environments and other challenging applications.

Calibration included

The QLA402 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.

Autoclavable and unstoppable

Description

QLA402 Custom Autoclavable Load Button Loadcell

Product Highlights And Features

Standing at 0.53in (13.5mm) × 0.16in (4mm) the QLA402 is a miniature, low profile, sterilizable, load button load cell with an extraordinarily robust monolithic design. Based on our patented (#US10527509B2) hermetic sealing technology, this high-quality sensor can withstand the harsh physical and chemical conditions in the autoclave and survive over a thousand cycles while providing consistent performance, providing a long service life, low maintenance, and low replacement costs while reducing material waste and cost per procedure.

Its small size and autoclavability offers incomparable value for advanced handheld medical tools that require haptic feedback capabilities as close to the surgical site as possible. This model can also be modified to suit OEM applications. FUTEK offers application and engineering resources during DFM/DFX stage upon request.

Designed for autoclave applications

The FUTEK QLA402 sensor is ideal for autoclave applications, such as smart laparoscopic and endoscopic tools. Its patented design was made to withstand harsh conditions such as high-pressure steam sterilization and operate reliably in environments with high temperature and pressure steam, bleach, and other high pH liquids. Other than autoclaves, the QLA402 is suitable for other critical areas such as aerospace and harsh industrial applications.

Patented hermetic sealing

QLA402 load cell employs the FUTEK’s patented, monolithic hermetically sealed design, which results in a robust, air-tight, and waterproof device suitable for unique and custom force-sensing requirements. Hermetically sealing the load cells protects the devices from the ingress of steam, liquids, and other particles in the autoclave, and especially at elevated temperatures and pressures.

Highest protection rating

Due to the patented technology, the QLA402 has an IP69K-rating, the highest protection against ingress of dust, liquids, and steam jets, meaning that it can withstand almost any harsh condition as well as over a thousand autoclave sterilization cycles

Miniature monolithic design

The QLA402 has a unique monolithic design that features protruding connector pins that have been hermetically sealed using a proprietary no-welding process, making the sensor very durable and capable of withstanding extremely harsh conditions. This technology also shrinks the package size, allowing the sensor to have its exceedingly low profile.

Flexible connection

Unlike the traditional load sensor with integrated cable, the FUTEK QLA402 has a connector output that increases flexibility and maintainability. The sensor has an integrated hermetically sealed pin header, with pins that protrude from the housing to provide easy-to-access electrical power and signal connections. This design provides connection flexibility, as users can directly solder wires or flex circuits onto the pin headers.

Powerful material

The QLA402 body has an excellent corrosion-resistant Inconel alloy body. The construction material is suitable for almost any fluid and has a high resistance to scaling and oxalic acid effects. Its outstanding oxidation and corrosion resistance at elevated temperatures makes the load cell ideal for harsh autoclave environments and other challenging applications.

Calibration included

The QLA402 has been tested by FUTEK’s world-class calibration department and is NIST traceable. We can also reduce hidden costs and setup time by calibrating your sensor with FUTEK electronics of your choice. In addition, we offer calibration to ANSI Z540-1 and ISO 17025 standards upon request.